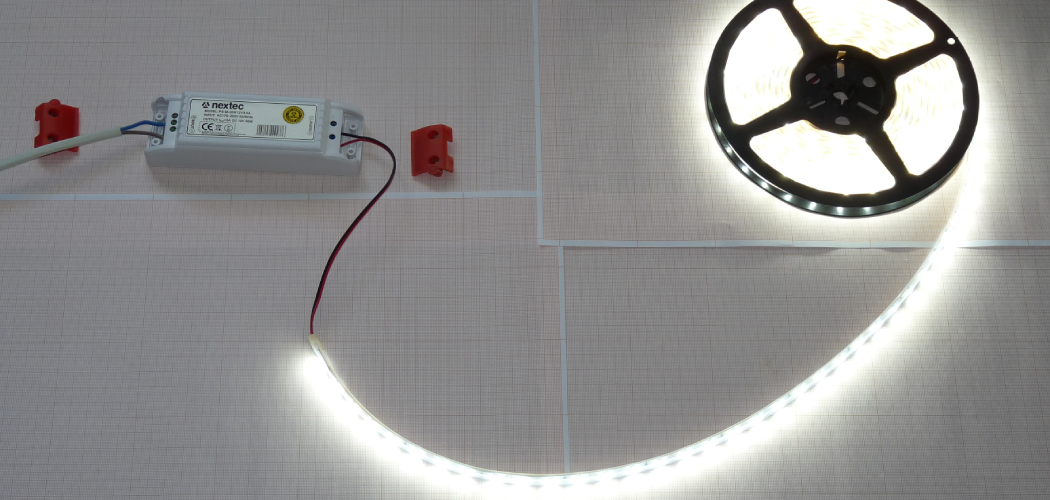

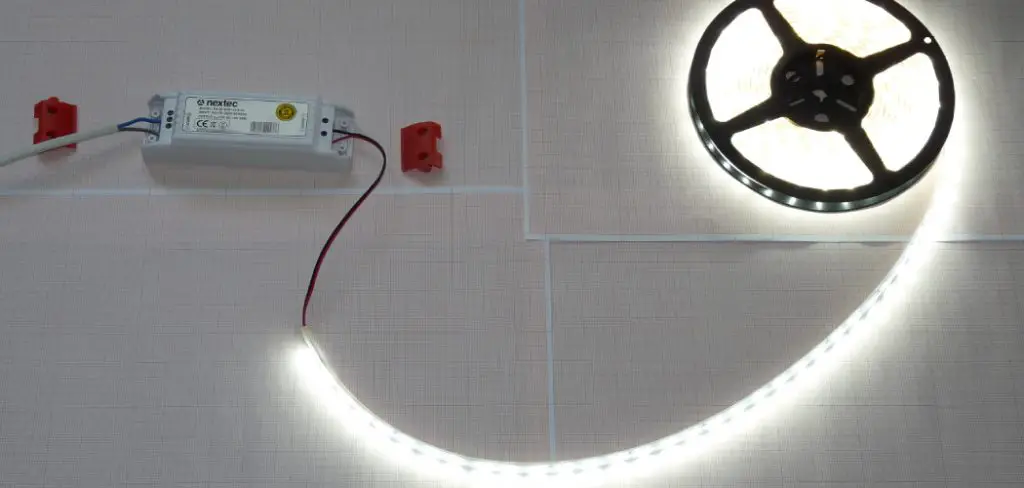

LED strips are becoming increasingly popular for lighting projects, as they are easy to install and use. Unfortunately, due to their thin design, LED strips can be easily damaged or ripped. Thankfully, if your strip is ripped, it’s not necessarily a death sentence for your lights; with the right tools and knowledge you can fix a rip in a LED strip relatively quickly and easily.

The advantage of learning to fix a ripped LED strip yourself is that it can save you the time and expense of having to buy an entirely new strip. It is also likely to be cheaper than paying someone else to do the job for you, as many hardware stores will carry some of the necessary materials.

Plus, if your LED strip goes out again in the future, you will be prepared to tackle the repair yourself. You can find step-by-step instructions on how to fix a ripped led strip in this blog article.

Step-by-step Instructions for How to Fix a Ripped Led Strip

Step 1: Inspect the Damage

Before you can fix the damage to your LED strip, you must first identify what the problem is. Inspect the strip for any signs of rips or tears in the actual strips surface. Now that you have identified where the rip is located on your LED strip, make sure to clean it with a damp cloth before proceeding with any repairs.

Step 2: Secure the Strip in Place

You will need to secure your LED strip in place before making any repairs. This can be done by attaching a piece of tape or string around it, so that it does not move while you are working.

Now that the strip is secured in place, you can start cutting out the damaged part. To do this, use a pair of scissors or a razor blade to carefully cut around the rip. Make sure to leave enough room for the repair material to adhere properly.

Step 3: Add Glue or Adhesive Tape

Once you have removed the damaged section from the LED strip, it is time to add glue or adhesive tape. If you are using glue, make sure that it is appropriate for the type of LED strip you have and apply it evenly to both sides of the rip.

Once the glue or adhesive tape has been applied, use a soldering iron or heat gun to secure it in place. Make sure to only apply enough heat for the adhesive to bond with the strip, as too much could damage the LEDs.

Step 4: Test The Strip

After you have secured the rip with glue or adhesive tape, it is time to test your LED strip. Turn the power on and make sure that all of the lights are functioning properly before proceeding. After testing the LED strip and ensuring it is functioning properly, you can reassemble it. Make sure that all of the connections are secure before turning on the power again.

Step 5: Connect to Power Source

Now that your LED strip has been repaired, you can connect it to your power source. Make sure that the connection is secure and all of the connections are tight before turning on the power.

Now that you have successfully repaired your LED strip, it is time to enjoy it! Turn on the lights and admire your work – you’ve just saved yourself a lot of money by avoiding having to buy a new one.

To make sure that your LED strip remains in good condition, check for any loose connections at least once every few months. This will help ensure that everything is working properly and avoid any unnecessary repairs.

Safety Tips for How to Fix a Ripped Led Strip

- Make sure you’re working in a well-ventilated, dust-free environment.

- Wear protective eyewear and gloves to protect your eyes and hands from any potential damage or injury that may occur during the repair process.

- Before beginning repairs, unplug the power source for the LED strip and be sure to properly ground yourself to prevent any static electricity from damaging the strip.

- Carefully cut away the ripped part of the LED strip with a pair of scissors. Do not attempt to pull it off as this will cause further damage to the LED strip and surrounding components.

- Use an adhesive or thermal paste to reattach the new section of LED strip onto the damaged one. Make sure there is a secure connection and the strips are lined up correctly to ensure proper functionality.

- Re-run the power source for the LED strip carefully to test its functionality before securing it in place.

- When finished, always dispose of any tools or materials used in a safe manner to prevent potential accidents or hazards from occurring while working on the LED strip.

When performing repairs on a LED strip, always be sure to read and follow all safety instructions provided by the manufacturer before starting any work. Additionally, it is important to properly inspect the LED strip for any signs of damage or wear before attempting any repair as this can cause further harm and could even lead to injury if not handled properly.

Are There Any Other Considerations You Should Be Aware of When Repairing a Led Strip?

When repairing a ripped LED strip, it is important to be aware of the fact that you may need to replace the entire LED strip if it has been damaged beyond repair.

Also, certain materials such as tape and glue may not adhere well to the surface of an LED strip, so make sure that any adhesive used is designed for use with LEDs before applying. In addition, be sure to wear protective gloves when working with the LED strip as it can contain sharp edges that may cut your skin.

In some cases, you may also need to use specialized tools when attempting to fix a ripped LED strip. For example, if the damage is extensive and involves multiple broken pieces of the strip, then you may want to consider purchasing a soldering iron to help reattach the broken connections.

Additionally, if you’re dealing with a complex wiring issue, then an oscilloscope or multimeter may be helpful in troubleshooting and repairing the LED strip.

What Are Some Signs That Your Led Strip is Not Being Fixed Properly?

If you attempt to fix a ripped or damaged LED strip and it does not seem to be working properly, there are some signs that can indicate the repair is not being done correctly.

The first sign of an improper repair is if your LED strip appears dimmer than normal after the repair. This could mean that the connections in the circuit have been compromised, resulting in insufficient power being delivered to the LEDs.

Another sign that your LED strip is not being fixed properly is intermittent flickering or failure of the LED lights after repair. This could indicate a poor connection or an insufficient voltage being supplied to the circuit, and can also be caused by defective components or components that were damaged during repair.

How Do You Clean the Led Strip Before and After Making a Repair?

Before you make a repair on a LED strip, it is important to make sure that the strip is clean. To do this, start by lightly dampening a lint-free cloth with water or rubbing alcohol and wiping away any dirt or residue from the area surrounding the rip.

Make sure to avoid getting any moisture into the rip itself. Once the strip is clean, you can begin your repair. After the repair is complete, it is a good idea to clean the strip again using the same methods as before.

This will help ensure that any dirt or contaminants are removed and that your repair job lasts as long as possible. If your LED strip has been exposed to water, you may need to use a specific cleaning solution designed for LED strips to ensure that all the moisture is removed and that all of the electrical connections are functioning properly.

After cleaning with a specialized solution, make sure to dry the strip completely by wiping it down with a cloth or using a low-heat hair dryer.

Is It Possible to Make the Repair Look Aesthetically Pleasing as Well as Secure and Functional?

Yes, it is possible to make a repair on a LED strip look both aesthetically pleasing and secure. If you have access to heat shrink tubing that matches the color of the strip, you can use this to cover up any seams or exposed wires. This will help create a finished look and make the repair less noticeable.

If you don’t have access to heat shrink tubing, you can use electrical tape or another adhesive to create a neat and clean look. Make sure that the adhesive used is rated for outdoor use, if applicable. This will help protect the repair from any weather elements it may be exposed to.

Finally, make sure to check your LED strip periodically after making any repairs in order to ensure that it is still functioning properly. This will help you catch any issues early and keep your LED strip looking its best.

Conclusion

In conclusion, fixing a ripped LED strip is not as difficult as it may seem. With the right tools and some patience, anyone can fix their damaged LED strip in no time. Even if you don’t have experience with electrical repair, following the steps we’ve outlined in this article will help you get your LED strip looking like new.

Remember to check for any exposed wires after you fix the strip, as these can be dangerous if not properly covered up. If you find yourself in need of any additional supplies or guidance while fixing your LED strip, feel free to reach out to us at our website and we’ll do our best to help you.

I hope this article has been beneficial for learning how to fix a ripped led strip. Make Sure the precautionary measures are followed chronologically.