Maintaining clean trailer light connections is crucial for both road safety and adherence to legal requirements. Dirty or corroded connections can lead to malfunctioning lights, posing significant risks for the driver and others on the road. By ensuring your trailer’s lights are functioning properly, you comply with traffic laws and contribute to safer towing experiences.

This article serves as a comprehensive guide on “how to clean trailer light connection,” addressing everything from the signs of dirty connectors to step-by-step cleaning instructions, allowing for optimal performance and safety of your trailer lights.

Types of Trailer Light Connectors

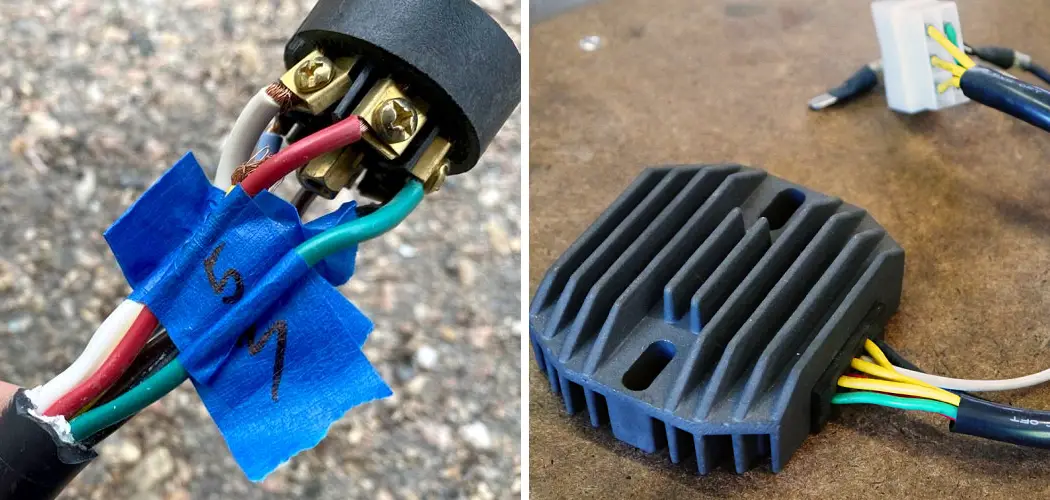

When it comes to hooking up your trailer’s lighting system, you’ll typically encounter two main types of connectors: the 4-pin flat and the 7-pin round. The 4-pin flat connector is the most commonly used for its simplicity and adequacy in handling basic lighting functions. This type includes pins for the left turn signal and brake light, the right turn signal and brake light, the tail or running lights, and the ground connection.

On the other hand, the 7-pin round connector accommodates larger trailers that require more functions beyond just the basic lighting. It includes connections for left and right turn signals, brake lights, tail lights, reverse lights, a ground wire, and two additional pins for auxiliary power and electric brakes. This connector is essential for trailers that carry heavy loads and, therefore, require direct integration with the vehicle’s braking system.

Additionally, other varieties of connectors, such as 5-pin, 6-pin round or square, and heavy-duty 7-pin commercial-grade connectors, cater to special towing needs or specialty trailers that may house batteries, winches, or require reverse lights. Each pin in these connectors is designed to carry a specific signal or power line, ensuring safe and regulation-compliant operation of the trailer’s lighting and auxiliary systems.

Recognizing Signs of Dirty Connections

Several telltale signs may become evident when trailer light connections are dirty or compromised. The most common symptoms include malfunctioning lights, which may not turn on when required or may not turn off when they should. Drivers may also notice flickering signals or brake lights, an issue that confuses other road users and can lead to dangerous miscommunications on the road.

In more severe cases, there could be a complete electrical failure resulting in a total loss of lighting functionality — such situations can be particularly perilous during night-time towing or in bad weather conditions when visibility is crucial.

These electrical issues not only increase the likelihood of accidents but can also result in legal repercussions if the driver is found to be non-compliant with road safety standards. Detecting and addressing these early warning signs is essential for maintaining road safety and adherence to legal requirements.

Potential Causes of Contamination

Contamination of trailer light connections can arise from various sources, each contributing to the degradation of the electrical system and reliability. Road debris is a primary culprit, as dirt and small particles can accumulate in the connector housing, interrupting the circuit’s integrity.

Exposure to the elements presents another significant challenge. Moisture from rain, snow, and high humidity can foster corrosion, particularly if salt is involved, as is common in areas with icy road conditions where salt is used for de-icing. This salty mixture accelerates corrosion, leading to poor connections and potential lighting failure.

Improper storage is another factor that affects the condition of trailer light connections. Left unprotected, connectors can gather dust and attract moisture, both of which can cause corrosion and oxidation. Consequently, without preventive care, such as using protective covers when the trailer is not in use or ensuring storage in a dry environment, the integrity of the connection is at risk.

It’s vital to recognize that each of these factors does not act alone but often in combination, exacerbating the contamination and causing progressive damage that can lead to functional and safety issues with the trailer’s lighting system.

Importance of Regular Cleaning

Regular cleaning of trailer light connections is an essential preventive maintenance step. By routinely removing dirt and corrosive substances, drivers can avoid costly repairs and ensure consistent, safe towing. This diligence is more than just a maintenance routine; it’s a proactive measure to prevent potential accidents caused by faulty lights.

Clean connections contribute to clear communication with other drivers through signals, thus averting misunderstandings and collisions. The few moments taken to clean these connectors can significantly impact the safety and longevity of the trailer’s electrical system.

Gathering Necessary Tools and Supplies

Before undertaking the task of cleaning your trailer light connections, it’s important to gather all necessary tools and supplies. You’ll need:

- Wire Brush: For scrubbing away rust and corrosion from metal surfaces.

- Electrical Contact Cleaner: A specialized spray designed to dissolve and remove contaminants without damaging the electrical components.

- Rubbing Alcohol: To clean and evaporate quickly, leaving no residue.

- Clean Cloths: For wiping down components after cleaning.

- Dielectric Grease: To apply post-cleaning, it protects electrical connectors from moisture and prevents corrosion.

- Protective Gloves: To keep your hands clean and safe from chemicals and sharp edges.

- Safety Glasses: To protect your eyes from flying debris and chemical splashes.

- Plastic Brush: A softer option for delicate areas where a wire brush might be too abrasive.

Each tool or supply has a specific purpose, from the wire brush’s robust cleaning capability to the protective qualities of dielectric grease that ensure the long-term integrity of the connections. Safety equipment such as gloves and glasses are essential to protect against potential hazards during cleaning.

How to Clean Trailer Light Connection: A Comprehensive Guide

Cleaning your trailer light connections is a critical maintenance task ensuring road safety. Follow this detailed step-by-step guide to keep your trailer’s lighting system in top condition.

1. Preparation

- Disconnecting the Trailer: Before starting, ensure the trailer is parked on flat ground, apply the parking brake, and disconnect your trailer from the towing vehicle to prevent any electrical short circuits.

- Ensuring Safety Measures: Put on protective gloves to keep your hands safe from chemicals and wear safety glasses to protect your eyes from any debris or chemical splashes during the cleaning process.

- Protecting Surrounding Areas: Place a drop cloth or old towel under the work area to catch any falling debris or spills. This will also ensure the cleaning agents do not damage the ground surface.

2. Initial Inspection

- Assessing the Severity of Contamination: Examine both the trailer and vehicle connectors for any visible corrosion, dirt, or debris. Determine if the contamination is surface level or if significant corrosion may have caused damage.

- Identifying Any Damage: If there’s any noticeable damage, such as frayed wires or deep corrosion, assess whether professional repair is needed before you proceed with cleaning.

3. Cleaning Process

- Selecting Appropriate Cleaning Solutions:

- For mild corrosion, a solution of vinegar and water can be effective.

- An electrical contact cleaner is recommended for heavy buildup due to its ability to dissolve and remove contaminants without damaging the electrical components.

- Cleaning Techniques for the Vehicle Side of Connector:

- Use the wire brush to gently scrub away rust and corrosion.

- Spray the electrical contact cleaner onto the metal surfaces, if necessary, and allow it to work for a few minutes.

- Use the plastic brush for delicate areas to avoid further damage by the wire brush.

- Wipe away the residue with a clean cloth.

- Use a small amount of rubbing alcohol on a cloth to clean off any remaining cleaner and debris, ensuring that it evaporates completely.

- Cleaning Techniques for the Trailer Side of the Connector:

- Repeat the same steps as described for the vehicle side, taking care to clean each pin thoroughly.

- Pay special attention to any areas where debris can accumulate and cause connectivity issues.

4. Emphasize Safe Handling of Chemicals and Proper Cleaning Methods

Always follow the instructions on the chemical cleaners and read all safety warnings. Work in a well-ventilated area, and avoid direct contact with the chemicals. Ensure that cleaning tools are not cross-contaminated between the use of different cleaning agents.

5. Final Touches

- Drying the Connection Thoroughly: Once the connectors are clean, allow them to air dry completely, or use a clean, dry cloth to pat them dry. Do not reconnect the trailer until there’s no moisture present.

- Checking for Residual Dirt: Inspect the connectors again and ensure no leftover dirt or debris. Use a clean cloth to lightly polish the metal surfaces if necessary.

- Applying Dielectric Grease for Protection: To finish, apply a small amount of dielectric grease onto the connection points to help prevent future corrosion and protect the metal from moisture. Do not overapply, as this might attract more dirt in the future.

By following these steps—and conducting them regularly—you will maintain a clear electrical signal from your towing vehicle to your trailer, ensuring safety and compliance with road standards.

That’s it! You’ve now learned how to clean trailer light connection effectively. Remember to conduct this maintenance task at least once a year to ensure your trailer’s electrical system is functioning correctly and safely. With proper care, you can extend the lifespan of your trailer light connections and avoid potential issues while out on the road.

Additional Tips and Tricks

Beyond the comprehensive guide, further strategies can simplify the cleaning endeavor and enhance effectiveness. For instance, utilizing Cotton Swabs for tight spots can facilitate the removal of dirt that brushes cannot reach.

Opt for swabs with longer handles to access, especially narrow areas. When handling cleaning agents, avoid those with harsh chemicals that might degrade the connectors over time. Household Items such as vinegar often suffice for mild cases of corrosion and are safer for both you and the environment.

Additionally, the way connectors are stored when not in use can significantly influence their longevity. Proper Storage Techniques involve keeping the connectors covered or wrapped to prevent exposure to the elements when the trailer is not hitched.

Consider using a small plastic bag and a rubber band to cover the vehicle-side connector and a designated plug cover for the trailer side. Regular Routine Checks, especially before a long trip, can help spot potential problems early. Implementing these tips will help during the cleaning process and preserve the quality and function of your trailer light connections for future use.

Troubleshooting Common Issues

While cleaning trailer light connections can often be straightforward, you might encounter persistent issues. If Stubborn Corrosion refuses to come off with standard cleaners, consider using a contact cleaner specifically designed for heavy corrosion. Alternatively, fine-grit sandpaper can gently abrade the affected area, removing the corrosion without damaging the metal.

In instances where you find Damaged Pins, if the damage is slight and does not hinder the connection, carefully straighten them out with needle-nose pliers. However, significant damage often requires replacing the entire connector. For this, consult your trailer’s manufacturer manual for the correct part number and installation guidelines.

Faulty Connectors resulting in inconsistent or no lighting might stem from internal wiring issues. First, ensure the problem isn’t with the towing vehicle’s socket by testing it with a circuit tester. If the vehicle’s socket is not the issue, closely inspect the trailer connector’s wiring for breaks or frays. Wire connectors can reconnect small breaks, but extensive damage may necessitate rewiring or professional assistance.

For complex electrical problems or when in doubt, it’s best to seek the help of a professional. An expert can safely manage intricate repairs while ensuring all safety standards are met, helping you maintain the integrity of your trailer’s lighting system.

5 Benefits of Cleaning Trailer Light Connections: Ensuring Your RV Safety and More

For RV enthusiasts and trailer owners, ensuring the safety and reliability of their rigs is paramount. An often overlooked yet vital aspect of trailer maintenance is cleaning trailer light connections. Neglecting these can lead to a slew of problems, from reduced visibility to potential electrical hazards. Dive into this listicle to discover why periodically cleaning these tiny connections can make a huge difference in your travel experiences.

1. Improved Safety

Better Visibility on the Road

Cleaning trailer light connections equate to ensuring that your signals, brakes, and markers shine brightly. A clear, unobstructed light helps you see the road better and makes you more visible to other drivers. Especially during adverse weather or low-light conditions, visible signals can be the difference between a smooth journey and a close call.

Reduced Risk of Accidents

Statistics show that many trailer-related accidents are due to malfunctions in lighting systems. Regular cleaning can significantly decrease the risk. By maintaining a high level of visibility, you’re alerting other motorists of your intentions on the road, reducing the likelihood of a collision.

2. Enhanced Durability

Prolongs the Lifespan of Trailer Lights

Accumulated dust, dirt, and corrosion can lead to premature failure of your trailer lights. The moisture and debris build-up act as a breeding ground for issues. Regular cleaning ensures that you’re temporarily avoiding problems and extending the lifespan of these essential safety elements.

Minimizes the Need for Replacements

When your lights are properly maintained, they require less frequent replacements. This saves you money and the time and effort involved in sourcing and installing new lights.

3. Optimal Functionality

Ensures Proper Lighting Operation

When trailer lights are clean, they operate as they should – consistently and reliably. This attention to maintenance guarantees all lights are visible and undistorted.

Prevents Electrical Issues

Corrosion is an electrical system’s worst enemy. Regularly cleaning your trailer light connections prevents this harmful buildup and the potential for more significant electrical issues related to your trailer’s lighting system.

4. Cost-Effectiveness

Saves Money on Repairs

Regular cleaning is a cost-effective preventative measure against lighting issues. Repairing your trailer’s lighting system can be pricey, particularly if the problem is caught late and causes further damage.

Increases Fuel Efficiency

Did you know that a malfunctioning lighting system can lead to an increase in drag? An underperforming system may not be as aerodynamic, which leads to a higher fuel consumption rate. By keeping your connections clean, you’re also managing your fuel efficiency.

5. Peace of Mind

Travel with Confidence

Knowing your trailer’s lights are clean and functioning properly provides peace of mind. This subtle reassurance can make a significant difference, especially during long hauls or when navigating unfamiliar roads.

Enjoy Stress-Free Towing

Stress-free towing isn’t just about the route; it’s about the journey being as smooth as possible. By taking the time to maintain your trailer’s light connections, you’re ensuring that one less thing can go wrong, and you can focus on enjoying your adventures.

Frequently Asked Questions About Trailer Light Connection Maintenance

Q: How Often Should I Clean My Trailer Light Connections?

A: It’s recommended to clean your trailer light connections at least once every few months or as needed. Frequent travelers or those in harsh climates may need to clean them more regularly to prevent corrosion and ensure optimal visibility.

Q: Can I Use Household Cleaners to Clean My Trailer Light Connections?

A: It’s best to avoid household cleaners as they can be too harsh and cause damage. Instead, use cleaners specifically designed for electrical components or a simple solution of soapy water followed by a thorough rinse and drying.

Q: What Should I Do if My Trailer Lights Still Don’t Work After Cleaning?

A: Check the bulbs to see if they need replacing. If new bulbs don’t fix the issue, inspect the wiring for damage and check the towing vehicle’s socket with a circuit tester. If you’re unable to identify the problem, it’s time to consult a professional.

Q: Is There a Way to Prevent Corrosion on My Trailer Light Connections?

A: Applying dielectric grease can help prevent corrosion by providing a moisture-resistant barrier. Make sure to apply it sparingly and only on clean connections to avoid attracting dirt.

Q: Are There Any Special Tools Required for Cleaning Trailer Light Connections?

A: Usually, no special tools are required for basic cleaning. A wire brush, fine-grit sandpaper, and a contact cleaner for heavy corrosion should suffice. For more complex maintenance, like rewiring, you may need wire strippers, crimpers, and a multimeter.

Q: Is It Necessary to Disconnect the Trailer Light Connections from The Power Source Before Cleaning?

A: Yes, for safety reasons, always disconnect your trailer light connections from the power source before performing any maintenance.

Conclusion

Clean trailer light connections are vital for safety during transport and are mandated by law for functional illumination. This guide has aimed to educate readers on “how to clean trailer light connections,” ensuring a reliable and brilliant display of lights to communicate with fellow motorists.

Regular maintenance prevents roadside hazards and shields you from potential legal complications due to non-compliant lighting. By incorporating the suggested practices, you can significantly mitigate the risk of accidents and retain the operational integrity of your trailer lights.

For additional guidance, refer to your trailer’s instruction manual and seek expert tutorials that delve deeper into maintenance techniques. Stay proactive about your trailer’s upkeep to ensure a safe journey every time you hit the road.