Navigating a boat safely requires visibility, both for the boat operator and for other vessels nearby. Properly wiring navigation lights is crucial not only for compliance with maritime regulations but also for ensuring nighttime visibility and safety on the water. This guide aims to provide a clear and concise step-by-step process for how to wire nav lights on a boat, helping you to stay safe and be seen. Whether you’re new to boating or looking to upgrade your vessel’s lighting system, these instructions will walk you through the essential procedures involved.

What Are Navigation Lights?

Navigation lights are essential components on a boat designed to enhance visibility, indicating the size, activity, and direction of travel of the vessel. These lights are typically color-coded: red for the port (left) side, green for the starboard (right) side, and white for the stern (rear) and masthead area.

Their primary function is to prevent collisions by allowing other vessels to determine your boat’s orientation and movement relative to their own, especially during low-light conditions such as dusk, dawn, or nighttime. Proper use of navigation lights ensures compliance with maritime law and contributes significantly to safe boating practices.

Why Wiring Them Correctly is Essential

Properly wiring navigation lights on a boat is crucial for several reasons, with safety being the foremost concern. Correct installation ensures that the lights function as intended, providing clear and unambiguous signals to other vessels regarding your boat’s position and movement.

This clarity helps prevent accidents and collisions, which can be especially dangerous on the water where visibility might be compromised. Moreover, accurate wiring is necessary to meet legal requirements and avoid potential fines or penalties for non-compliance with maritime regulations.

Well-maintained and correctly-wired navigation lights also help in conserving the boat’s electrical system by preventing overloads and ensuring durability. Ultimately, investing the time and effort to wire them correctly contributes significantly to the overall safety and functionality of your boating experience.

10 Methods How to Wire Nav Lights on a Boat

1. Understand the Electrical Requirements and Regulations

Before starting the process of wiring navigation lights on your boat, it is crucial to first understand the electrical requirements and regulations set by local maritime authorities. Navigation lights are not just for aesthetic purposes; they are a critical safety feature that must comply with standards, such as the International Regulations for Preventing Collisions at Sea (COLREGs).

These regulations dictate the color, positioning, and range of visibility for navigation lights to ensure other vessels can identify your boat’s size, direction, and activity. To adhere to these rules, ensure you purchase lights rated for marine use, with the appropriate voltage, and designed for the vessel’s size. Most small boats use a 12-volt DC system, which is typical for marine electrical applications.

2. Gather the Necessary Tools and Materials

Once you’ve clarified the regulations and requirements, the next step is to gather all the tools and materials needed for the installation. Wiring navigation lights requires certain basic tools: a wire stripper, crimping tool, marine-grade wiring, heat-shrink connectors, electrical tape, and a multimeter for testing. You will also need marine-grade fuse blocks, switches, and possibly circuit breakers to ensure safe and reliable operation. Marine-grade materials are specifically designed to resist corrosion, UV damage, and exposure to moisture, which are unavoidable conditions in a boating environment. Investing in high-quality marine components will extend the longevity and safety of the electrical system.

3. Plan the Wiring Route

Effective planning is key to a successful wiring installation. Take the time to map out the path your wires will take from the power source, usually the boat’s battery, to the navigation lights. Try to run wires along existing paths or routes where they will be protected from damage. Avoid placing them in areas prone to water accumulation or sharp objects that could puncture or wear down the insulation. It’s also best to keep wiring away from fuel lines or other potential hazards. Labeling your wires as you go along will simplify troubleshooting and future maintenance.

4. Select the Proper Wire Gauge

Choosing the correct wire gauge is crucial to ensure the safe operation of your navigation lights. The gauge of the wire needs to be matched to the current draw of the lights and the distance from the power source to the lights. Typically, for a 12-volt system, 16-gauge marine-grade wire is adequate for most navigation light installations. However, if you are running the wires over longer distances, you may need to use a lower gauge (thicker) wire to compensate for voltage drop. Marine-grade wire is tinned, which offers better resistance to corrosion and should be used instead of standard copper wire.

5. Install a Dedicated Switch Panel

Your navigation lights need to be controlled by a switch, which can either be part of an existing control panel or a dedicated switch for the lights. Using a marine-grade switch panel ensures that the control of your navigation lights is both accessible and protected from moisture. Some boaters prefer a switch with multiple functions, such as one that controls both the running lights and anchor light, or a switch that has a built-in LED to indicate when the lights are on. Make sure that the switch you choose is rated for the electrical load it will carry.

6. Install an Inline Fuse

Protecting your navigation light circuit with an inline fuse is critical to prevent electrical failures and potential fires. An inline fuse is a simple device placed in the positive wire between the battery and the switch to protect the circuit from overcurrent situations. It is important to choose the correct fuse size based on the current draw of your lights. For example, if your navigation lights draw 3 amps, you should use a fuse slightly larger than that, typically a 5-amp fuse. A marine-grade fuse block is also a good option for organizing multiple circuits in one location.

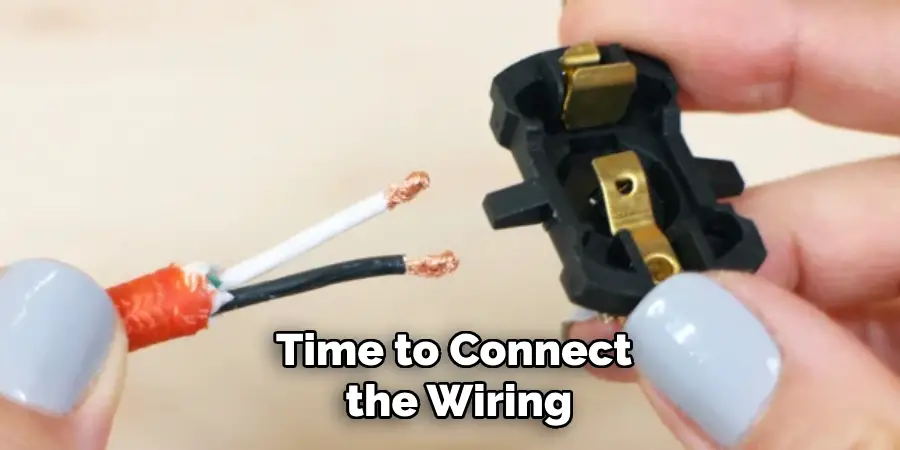

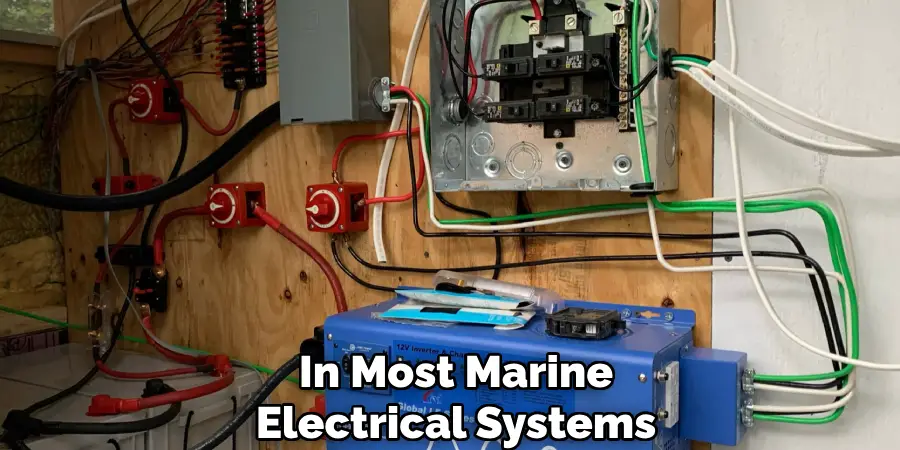

7. Connect the Positive and Negative Wires

In most marine electrical systems, the negative terminal of the battery is connected to a common grounding bus. When wiring your navigation lights, you will run the positive wire from the light to the switch, and then from the switch to the positive terminal of the battery. The negative wire from the navigation light is connected directly to the negative bus or negative terminal of the battery. Ensure that all wire connections are solid and free of corrosion. Use marine-grade crimp connectors and heat-shrink tubing to protect the connections from moisture and ensure a secure, long-lasting bond.

8. Test the Voltage and Continuity

Before finalizing the wiring, use a multimeter to test the voltage and continuity of the circuit. Start by testing the voltage at the battery to ensure it is providing sufficient power. Then, with the switch turned on, check the voltage at the light fixture to ensure that the power is reaching the light. If the light isn’t turning on, test the continuity of the wire to ensure there are no breaks or bad connections along the route. Testing these aspects early can save you significant troubleshooting time later.

9. Mount the Navigation Lights

Once the wiring is confirmed to be working correctly, the next step is to physically mount the navigation lights. The exact placement of the lights depends on your boat’s size and type, but generally, the red and green running lights should be mounted at the bow, with the red on the port (left) side and green on the starboard (right) side. The white stern light is mounted at the rear of the boat, while the all-around white light, used when anchored, should be placed as high as possible to ensure visibility. Use stainless steel screws and marine-grade sealant to secure the lights and protect the installation from water intrusion.

10. Perform a Final System Test

After the lights are mounted and the wiring is complete, perform a final test of the entire system. Turn on the boat’s electrical system and test each light in turn. Verify that the red, green, and white lights all illuminate as intended and that they are visible from the required distances. Check the switch operation to ensure that the correct lights turn on and off according to their purpose (e.g., running lights while moving, anchor light when stationary). It’s also a good idea to test the system at night to ensure visibility is adequate for other vessels. Regularly checking your navigation lights as part of your routine boat maintenance will help prevent future issues.

Conclusion

Properly installing and maintaining navigation lights on your boat is essential for ensuring safety on the water. By carefully planning the wiring routes, choosing the appropriate materials, and adhering to best practices for electrical connections, you create a reliable system that enhances visibility and communication with other vessels. Regular checks and maintenance of the navigation lights will not only prevent unexpected issues but also prolong the lifespan of the entire setup. Thanks for reading our blog post on how to wire nav lights on a boat! We hope you found it helpful and informative.