LED lighting offers many advantages over metal halide. It’s more energy-efficient, lasts longer, and is much cooler in temperature. LED lights can also be dimmed and have better color rendering than metal halide lights, making them a great choice for any type of lighting application. Converting from metal halide to LED can drastically reduce energy bills and maintenance costs.

One of the biggest advantages of converting from metal halide to LED is that LED lighting is far more energy efficient than traditional metal halide lighting. Traditional metal halide light bulbs are known for their brightness, but they also use a lot of electricity to create this same level of brightness.

Converting to LED lighting can drastically reduce energy consumption by up to 75%.In this blog post, You will learn in detail how to convert metal halide to led.

Step by Step Processes for How to Convert Metal Halide to Led

Step 1: Inspect Your Current Light Fixture

Before you begin converting your metal halide light to LED, it is important that you inspect the current fixture. Make sure that all of its components are in good working order, and if not, replace them before beginning the conversion process.

Step 2: Install the Replacement LED Driver

Once you have inspected and prepared your existing fixtures, you can start the conversion by installing a replacement LED driver. This device will provide power to the LED bulbs and should be connected securely to both the ballast and fixture.

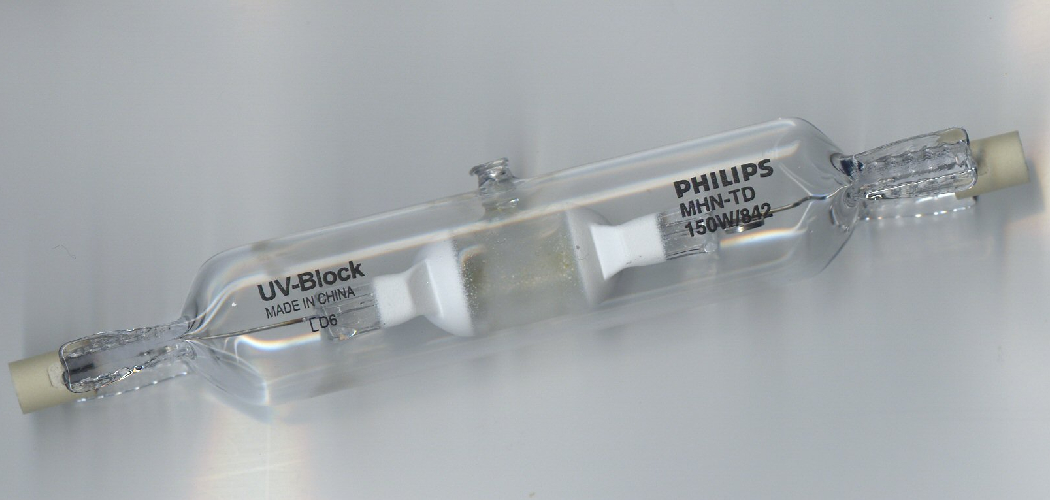

Step 3: Remove the Metal Halide Bulbs from Fixture

After successfully connecting your LED driver, you can now remove the metal halide bulbs from the existing fixtures. Make sure to disconnect them carefully and store them away from the LED bulbs as they may otherwise overheat.

Step 4: Install the Replacement LED Bulbs

Once you have removed all of the metal halide bulbs from the existing fixture, you can now proceed with installing your LED replacement bulbs. Ensure that each bulb fits securely in the fixture and is properly wired.

Step 5: Ensure the LED Driver is Functioning Properly

After installing your new replacement LED bulbs, it is important to ensure that the LED driver is functioning properly. Check the connections and ensure that the power supply provides enough energy for the lights to work.

Step 6: Configure Your Lighting Settings

Now that you have successfully installed your LED bulbs and driver, it is time to configure your lighting settings. Depending on what type of LED bulb you are using, there are a few different options for adjusting the brightness, color temperature, and intensity.

If you want to save energy and money, you should also consider scheduling automatic on/off times for your LED lights. This will allow you to set your lights to turn off during the day or night when they are not being used in order to conserve energy.

Step 7: Test the New Lighting System

Once you have configured all of the settings and installed your new LED bulbs, you should test the new lighting system to ensure it is functioning properly. Turn on all the lights and ensure they provide the desired brightness and light coverage.

Finally, if you want to save even more money, you should consider monitoring your energy consumption after converting to LED. This can help you identify areas where you may be able to reduce electricity usage and better manage your energy costs.

Step 8: Enjoy Your New LED Lights

After completing all of the above steps, you can now enjoy the benefits of LED lighting in your home or commercial space! LED lighting is more efficient than traditional metal halide lights, which means you will save energy and money in the long run. By following these steps, you can easily convert your metal halide lighting to LED and enjoy all of the benefits that this type of technology provides.

Safety Tips for How to Convert Metal Halide to Led

- Ensure you have all the necessary tools, parts and materials before beginning the conversion process. This includes LED bulbs, a voltage tester, safety goggles and gloves, wire cutters and strippers, electrical tape, and connectors.

- Make sure to turn off all power to the area you will be working in for safety. If you are working with higher voltages, make sure the power is off at the circuit breaker too.

- Keep in mind that LEDs require a more powerful ballast than those used for metal halide bulbs, so if you are changing out only one bulb, consider replacing the entire ballast.

- Only use LED lamps that are specifically compatible with metal halide fixtures.

- Ensure you properly ground your equipment and use the correct wattage for each lamp.

- Inspect all wiring and connections before powering on, including any switches or dimmers that may be used in the system.

- After completing the installation, always double-check the wiring and be sure all power is off before beginning.

Following these safety tips can help you ensure a successful conversion when switching from metal halide to LED lighting. If done correctly, you can enjoy the energy savings and improved LED lighting without compromising safety.

How Much Does It Cost to Convert From Metal Halide to Led?

The cost of converting from metal halide to LED can vary depending on the size of the lighting fixture and how many watts the bulb will consume. Generally, an LED lightbulb is more expensive than a metal halide one, but this comes with a much longer lifespan, lower energy bills, and improved brightness. For example, replacing a 400-watt metal halide bulb with a 150-watt LED can save up to 65 percent in energy costs.

When it comes to installation, the cost of converting from metal halide to LED depends on the size and type of lighting fixture being replaced as well as any additional wiring or retrofitting required. In addition, labor costs for installation can vary greatly depending on the complexity of the job. For a straightforward replacement, costs typically range from $200 to $500.

Are There Any Safety Concerns When Converting From Metal Halide to Led?

When it comes to converting from metal halide to LED lighting, there are some important safety concerns that you should be aware of. This is especially true if the conversion is being done in a commercial or industrial setting. Here are some of the most important safety considerations:

- Make sure all electrical connections are properly made with the correct wiring. Any incorrect connections could create a potential fire hazard.

- Before beginning the conversion, properly disconnect power and ground all equipment to prevent any electrical shock or contact with high-voltage lines.

- Before starting your project, you understand the local codes and regulations regarding lighting installations, conversions, and repairs.

- Make sure all LED fixtures are UL listed and have passed all safety tests. Safety certifications should be visible on the luminaire itself.

- Stay clear of any exposed wiring, switches, or other components when the electricity is turned back on after the conversion is complete.

Following these safety tips will help ensure that your conversion from metal halide to LED lighting is done safely and that any potential hazards are avoided.

Is There Any Additional Maintenance Required for LEDs After the Conversion Process?

The LED light fixtures that result from a metal halide to LED conversion usually require minimal additional maintenance. The most important thing for LEDs is making sure that the fixtures are kept clean and free of dust accumulation, as this can negatively impact the performance of the lights.

Additionally, it’s important to make sure that any protective covers or lenses remain intact to prevent damage and maintain a safe operating environment. Other than these basic maintenance steps, LEDs typically require no additional care after the conversion process.

The main benefit of converting metal halide to LED is the energy savings they provide and their long life span—far outlasting most other types of lighting. This means that you don’t have to worry about replacing the LED bulbs and fixtures as often, meaning less money is spent on maintenance over time.

Additionally, the lack of UV light emitted by LEDs reduces any risk of fading or damage caused by traditional lighting systems.

Are There Any Special Considerations When Converting From Metal Halide to LED?

When converting from metal halide to LED lighting, there are some considerations that you should take into account to ensure your conversion is successful. First, the temperature is a major factor in determining the performance of LED lighting.

LEDs tend to perform best when operating at lower temperatures than metal halides; therefore, choosing an appropriate fixture is important based on your space’s environment and climate.

In addition, fixtures should be selected based on the wattage and color temperature of the LED bulbs. Since LED lights are more efficient than metal halides, they will require less wattage to produce the same amount of light. Similarly, the color temperature of an LED lamp should match that of a metal halide lamp for a successful conversion.

Finally, it is important to remember that LED lighting systems require different voltage than metal halides, so you may need to check if your existing wiring can support the new system. If not, it may be necessary to upgrade your wiring before converting to LED lighting.

Are There Any Potential Risks Associated With Converting From Metal Halide to Led?

When converting from metal halide to LED lighting, there are a few potential risks associated with the process. Firstly, there is the possibility of interference with the existing electrical system in your facility. Possible disturbances may include overvoltage and equipment failure due to incorrect wiring or poor connections.

Secondly, it’s important to remember that LEDs usually operate on a lower voltage than metal halide fixtures, meaning that any existing wiring may need to be upgraded.

Finally, there is the potential for reduced output due to the incorrect selection of the LED lighting solution. It’s important to ensure that you have the correct replacement in terms of color temperature, luminosity, and power consumption. Considering these factors will help ensure a successful and safe conversion from metal halide to LED lighting.

To minimize any risks, it is highly recommended that you seek professional advice or assistance when undertaking this process. With the right guidance, converting your facility’s lighting system can be an easy and efficient process with no adverse effects on safety or performance.

Are There Any Environmental Benefits to Using Led Lighting Instead of Metal Halide?

Led lighting is considered to be a more environmentally friendly option than metal halide lighting. Led lights use significantly less energy and produce less heat, meaning fewer resources are used in their production and maintenance of them. Additionally, they contain no mercury or other hazardous materials, making them safe for disposal as well.

The long life span of LEDs also means fewer replacements are needed, reducing the amount of waste generated by lighting. By converting to LED lighting, you can help reduce your company’s environmental impact and save money in the long run.

LED lights also provide better quality light compared to metal halide bulbs, as they generate more natural-looking colors that allow people to see clearly and comfortably. This can improve the working environment for your employees and reduce eye strain, leading to increased productivity and reduced stress levels.

Overall, converting from metal halide to LED lighting will provide both environmental benefits and savings in energy costs. With their long life span, lower energy consumption, and higher quality light output, LED lights are an ideal choice for commercial and industrial applications.

Conclusion

The biggest disadvantage to converting from metal halide to LED is the cost. LEDs are more expensive than traditional lighting options and require an initial investment that may not be feasible for some people or businesses. Additionally, additional costs may be associated with installation, depending on the complexity of the setup.

In conclusion, converting from metal halide to LED lights is not a difficult process that requires careful planning and consideration beforehand. It is important to consider the wattage of your current fixture, the number of fixtures that need replacing, and the desired Kelvin temperature for your lighting system.

I hope this article has been beneficial for learning how to convert metal halide to led. Make Sure the precautionary measures are followed chronologically.