Wiring tunnel light is an important task that needs to be done correctly to ensure the proper functioning of the light. Tunnel lights are essential for providing illumination along underground passages, such as tunnels, mines, and roadways. They not only increase safety by improving visibility but also help drivers and pedestrians navigate through dark or hazardous areas.

In this guide, we will walk you through the step-by-step process of how to wire tunnel light. We will cover basic safety precautions, necessary tools and materials, and the actual wiring process. So, if you are planning to install a tunnel light or want to learn how to wire one correctly, keep reading!

Understanding Tunnel Lighting Requirements

Before we dive into the wiring process, it is crucial to understand the lighting requirements for tunnels. This will help you make informed decisions about which type of tunnel light and wiring method to use.

The primary purpose of tunnel lights is to provide sufficient illumination so that drivers and pedestrians can see clearly while traveling through tunnels or underground passages. The level of brightness required depends on various factors such as the length and width of the tunnel, curvature, traffic volume, and speed limit. Generally, the recommended lighting level for tunnels is measured in Lux (lx) or Lumen (lm) per square meter.

Apart from providing an adequate amount of light, tunnel lights must also be reliable and durable. Tunnels can experience harsh conditions such as high humidity, temperature fluctuations, and vibrations from vehicles passing through. Therefore, the wiring must be done correctly to ensure the longevity of the light and reduce maintenance costs.

Tools and Materials You Will Need to Wire Tunnel Light

- Wire stripper

- Electrical tape

- Screwdriver (flat-head and Phillips head)

- Pliers

- Voltage tester

- Wire connectors/wire nuts

- Junction box

- Light fixture

- Appropriate wires (depending on the voltage of the light)

Step-by-step Guidelines on How to Wire Tunnel Light

Step 1: Choose the Right Light Fixture

Before starting the wiring process, you should choose a suitable light fixture for your tunnel. Make sure the fixture has appropriate voltage and is designed to withstand harsh conditions like moisture, dust, and temperature changes. This will ensure the longevity of your tunnel light. If you are unsure about the suitable voltage for your tunnel light, consult a licensed electrician.

Step 2: Conduct a Thorough Inspection of the Tunnel

Before installing the light fixture, conduct a thorough inspection of the tunnel to identify any potential hazards or obstructions that may interfere with the wiring process. This is also important for determining the ideal location for your light fixture. Make sure there are no exposed wires or flammable materials near the installation area. If you find any potential hazards, address them before proceeding with the wiring process.

Step 3: Turn Off the Power

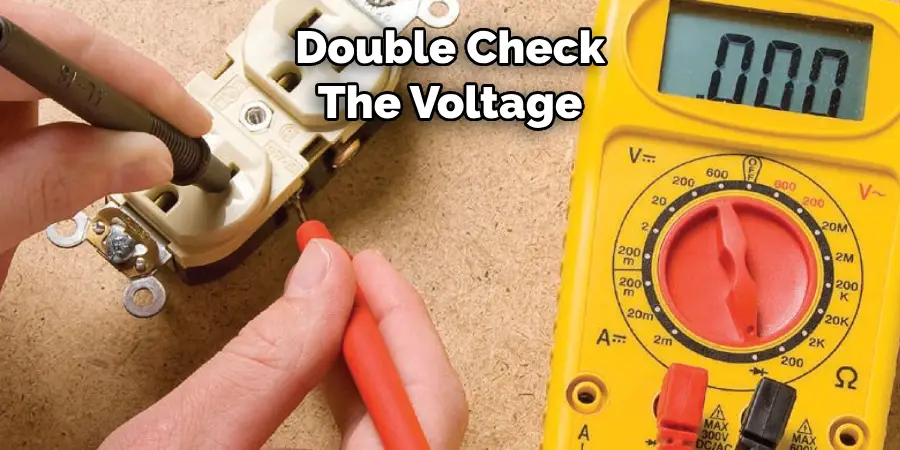

Before beginning the wiring process, turn off the power supply to avoid any electrical accidents. Use a voltage tester to confirm that the power is indeed turned off. Safety should always be your top priority when dealing with electricity. This step is crucial, especially when working with underground tunnels that may have unstable wiring or power sources. Make sure to follow all safety precautions during this step, including wearing insulated gloves and using a non-contact voltage tester.

Step 4: Prepare the Wires

Using a wire stripper, carefully remove the insulation from both ends of the wires that will be connected to the light fixture. Make sure to leave enough exposed wire for a proper connection. Preparing the wires beforehand will make the wiring process easier and more efficient. Make sure to double-check the voltage of the wires before proceeding.

Step 5: Connect the Wires

Using wire connectors or wire nuts, connect the black (hot) wire from your power supply to the black wire on your light fixture. Repeat this step for the white (neutral) wires and then for the green or copper (ground) wires. Make sure the connections are tight and secure. You can also use electrical tape to further secure the connections.

Step 6: Install the Light Fixture

Carefully install the light fixture onto the junction box, aligning it with the mounting screws. Make sure it is securely attached and level. Use a screwdriver to tighten any screws if necessary. If your light fixture has multiple bulbs, make sure they are all screwed in correctly. While installing the light fixture, make sure not to damage any of the connections made in the previous step.

Step 7: Test the Light

Once everything is properly installed and connected, turn on the power supply and test your newly wired tunnel light. If it does not turn on, double-check all of your connections and make sure the power supply is turned on. If you are still having issues, consult a licensed electrician. If the light turns on, congratulations, you have successfully wired your tunnel light!

Following these step-by-step guidelines will ensure that your tunnel light is wired correctly and will provide safe and reliable lighting for years to come. Remember, safety always comes first when working with electricity, so make sure to follow all safety precautions throughout the wiring process. Happy lighting!

Additional Tips and Tricks to Wire Tunnel Light

- If you are installing multiple tunnel lights, make sure to wire them in parallel rather than in series. This will ensure that if one light goes out, the others will remain lit.

- When dealing with underground tunnels, it is important to consider environmental factors such as moisture and dust. Make sure to use waterproof junction boxes and light fixtures designed for wet or dusty conditions.

- Regularly inspect and maintain your tunnel lights to ensure they continue functioning properly and safely. Replace any damaged or worn-out parts immediately.

- If you are unsure about any part of the wiring process or do not feel comfortable doing it yourself, always seek professional help from a licensed electrician. It is better to be safe than sorry when dealing with electricity.

- Consider installing motion-activated or timer-controlled lights for added energy efficiency and convenience.

- Always make sure to turn off the power supply before changing or inspecting any wiring in your tunnel light system.

- Familiarize yourself with local building codes and regulations before beginning any electrical work. This will ensure that your installation is done safely and up to code.

- If you are using a ladder to install the light fixture, make sure it is secure and placed on a stable surface before climbing up. Have someone assist you in holding the ladder for added safety.

By following these additional tips and tricks, you can ensure that your tunnel light system is not only wired correctly but also functional, safe, and efficient. Remember to always prioritize safety and consult a professional if needed. Now go forth and light up those tunnels! No need for any fancy termination phrases – just keep the content flowing and informative! Happy wiring!

Things You Should Consider to Wire Tunnel Light

1. The first thing you should consider before wiring your tunnel light is the type of light fixture you will be using. There are various types available, such as LED, fluorescent, and halogen lights. Each type has its unique requirements for wiring.

2. It is also important to consider the power supply for your tunnel light system. Make sure it can handle the voltage and wattage needed for your light fixture.

3. Before purchasing any materials or tools for the wiring process, make sure to accurately measure and plan out the placement of your tunnel lights. This will ensure that you have all the necessary components and avoid any extra trips to the store.

4. When working with underground tunnels, it is important to consider the length and accessibility of the wires. Make sure they are long enough to reach the power supply and light fixture and can be easily accessed for maintenance or repairs.

5. If you are using a junction box for your wiring, make sure it is properly grounded to prevent any electrical hazards.

6. Plan out the positioning of your tunnel lights carefully. Consider factors such as lighting direction, spacing between lights, and potential obstructions that could affect the effectiveness of your light system.

7. Always use proper safety gear when working with electricity, such as gloves and safety glasses. Never work on any wiring or electrical components if you are not feeling well or under the influence of drugs or alcohol.

8. If you encounter any issues during the wiring process, do not hesitate to stop and seek help from a professional. It is always better to be safe than sorry.

9. Lastly, make sure to thoroughly read and follow the manufacturer’s instructions for your light fixture and any other materials you are using. This will ensure that everything is wired correctly and functioning as intended.

By considering these important factors, you can ensure a successful and safe wiring process for your tunnel lights. Remember, always prioritize safety and never hesitate to seek professional help if needed. Happy wiring!

Maintenance Tips for Tunnel Light

1. Regularly clean your tunnel lights to remove any dust or debris that may accumulate on the surface and affect their brightness.

2. Inspect the light bulbs periodically and replace them if they are dim or burnt out. This will ensure consistent lighting and extend the lifespan of your tunnel lights.

3. Keep an eye out for any signs of damage, such as cracks or breaks, in the light fixture or wiring. If you notice any issues, address them immediately to prevent potential hazards.

4. It is also important to check the connections and wiring periodically for any loose or damaged parts. Tighten or replace them as needed.

5. If your tunnel lights are exposed to extreme weather conditions, consider investing in weatherproof covers or enclosures to protect them from damage.

6. Regularly test the functionality of your tunnel light system, including any timers or motion sensors if applicable. This will ensure they are working correctly and detect any issues that may arise.

7. Refer to the manufacturer’s instructions for specific maintenance recommendations for your light fixture and follow them accordingly.

8. If you notice any unusual changes in the brightness or quality of your tunnel lights, do not hesitate to seek professional help. It is better to address any issues early on rather than waiting for them to escalate.

By following these maintenance tips, you can ensure that your tunnel light system continues functioning properly and efficiently. Regular upkeep will also save you time and money in the long run by avoiding potential repairs or replacements. Keep those tunnels well-lit and maintained!

Troubleshooting Common Issues to Wire Tunnel Lights

1. If your tunnel light is not turning on, first check the power supply and make sure it is properly connected. Also, ensure that the light fixture itself is securely attached to the wiring.

2. If your light flickers or dims when turned on, there may be a loose connection in the wiring. Turn off the power and check all connections to tighten or replace as needed.

3. If you notice a buzzing sound coming from your light fixture, it could be due to a loose or faulty ballast. Consult the manufacturer’s instructions for troubleshooting and replacement guidance.

4. Another common issue is when only one section of your tunnel lights is not working. This could indicate a wiring or connection issue in that specific area. Check all connections and wiring in that section to address the issue.

5. If you are experiencing issues with your light timer or motion sensor, refer to the manufacturer’s instructions for troubleshooting and calibration instructions.

6. In case of any electrical hazards or malfunctions, turn off the power immediately and do not attempt to fix it yourself. Seek professional help instead.

By understanding these common issues and how to troubleshoot them, you can quickly and efficiently fix any problems with your tunnel light system. Always prioritize safety and seek help if needed. Keep those tunnels well-lit!

Precautions Need to Be Followed for Wiring Light

- First and foremost, ensure that the power supply is turned off before starting any wiring work. This will prevent any potential electrical hazards.

- Wear proper safety gear, such as gloves and safety glasses, when working with electricity to protect yourself from accidents.

- Before drilling or cutting into any walls or surfaces for wiring, make sure there are no hidden wires or pipes that could be damaged.

- Use appropriate tools and equipment for the wiring process, and handle them with care to avoid any accidents or damage.

- If you are unsure about any step of the wiring process, do not hesitate to seek help from a professional electrician.

- Make sure to follow all local building codes and regulations when installing your tunnel light system.

- Do not overload your circuit by connecting too many lights to one power source. This could cause electrical hazards and also affect the performance of your lights.

- Regularly check and maintain your wiring connections to ensure they are secure and functioning properly.

By following these precautions, you can minimize the risks associated with wiring tunnel lights and ensure a safe and successful installation process. Prioritize safety above all else. Happy wiring!

Frequently Asked Questions

Do I Need Any Special Tools for Wiring Tunnel Lights?

Yes, you will need basic electrical tools such as wire cutters, pliers, and a screwdriver. It may also be helpful to have a voltage tester to ensure the power is off before starting work.

Can I Install Tunnel Lights on My Own, or Should I Hire a Professional?

It is recommended to hire a professional electrician for the installation process, especially if you have little experience with electrical work. This will ensure the job is done correctly and safely.

What Kind of Wiring Should Be Used for Tunnel Lights?

The type of wiring will depend on the specific light fixture and the distance between the lights. Generally, it is recommended to use 14-gauge or 12-gauge wiring for tunnel lights.

Can I Use LED Lights for Tunnel Lighting?

Yes, LED lights are a popular and energy-efficient option for tunnel lighting. Make sure to check the wattage and voltage requirements of your light fixtures before purchasing LED bulbs.

How Often Should I Check and Maintain My Tunnel Lights?

It is recommended to check and maintain your tunnel lights at least once a year, or more frequently if they are exposed to extreme weather conditions. Regular maintenance will ensure their longevity and efficiency.

What Should I Do If My Tunnel Lights Malfunction or Stop Working?

If your tunnel lights are not functioning correctly, first check the power supply and connections. If the issue persists, seek professional help to troubleshoot and address any problems. Do not attempt to fix electrical issues yourself.

Conclusion

Now you know how to wire tunnel light systems and troubleshoot common issues that may arise. Remember to follow the precautions and seek professional help if needed for a safe and successful installation process. Regular maintenance will keep your lights functioning properly, ensuring well-lit and safe tunnels for everyone to use. If you have any further questions or concerns, consult the manufacturer’s instructions or contact a professional electrician for assistance. Happy lighting!