Shop lights are an essential component in crafting a well-lit, efficient workspace. Whether you’re working in a garage, workshop, or basement, these fixtures provide the bright illumination necessary for detailed tasks and maintaining safety.

Various types of shop lights are available, including LEDs, which are energy-efficient and long-lasting; fluorescents, known for their widespread utility and cost-effectiveness; and incandescents, which provide a warm light, though they are less common due to their higher energy consumption. The purpose of this article is to offer a comprehensive, step-by-step guide on how to wire shop lights safely. This guide is structured to assist both beginners and seasoned DIY enthusiasts, enabling them to achieve a professional result that ensures a reliable and well-illuminated environment.

Tools and Materials Needed

Having the right tools and materials on hand is essential to successfully wire shop lights. Here’s a list of what you’ll need:

- Shop Lights (LED, Fluorescent, etc.): Depending on your needs, you can choose from various types of shop lights. LED lights are often preferred due to their energy efficiency and long lifespan, making them cost-effective over time.

- Wire (14/2 Romex or 12/2 for Heavier Loads): Selecting the appropriate wire gauge is crucial, usually 14/2 is sufficient for standard loads, but 12/2 is recommended for heavier electrical loads, subject to local building codes.

- Wire Nuts: These are essential for safely securing wire connections, preventing electrical shorts, and ensuring stable connectivity.

- Wire Strippers: A vital tool for stripping insulation from the wire ends, necessary for making electrical connections.

- Electrical Tape: Used to insulate and secure wire connections, providing additional safety against potential electrical hazards.

- Screwdriver or Drill: The mounting hardware for shop lights needs to be installed, and the choice depends on the fixture requirements.

- Circuit Tester: Essential for confirming that the power is off, ensuring safety before working with electrical wires.

- Ladder: Required to safely reach ceilings or high areas during installation, providing stable access for mounting and wiring tasks.

Safety Precautions

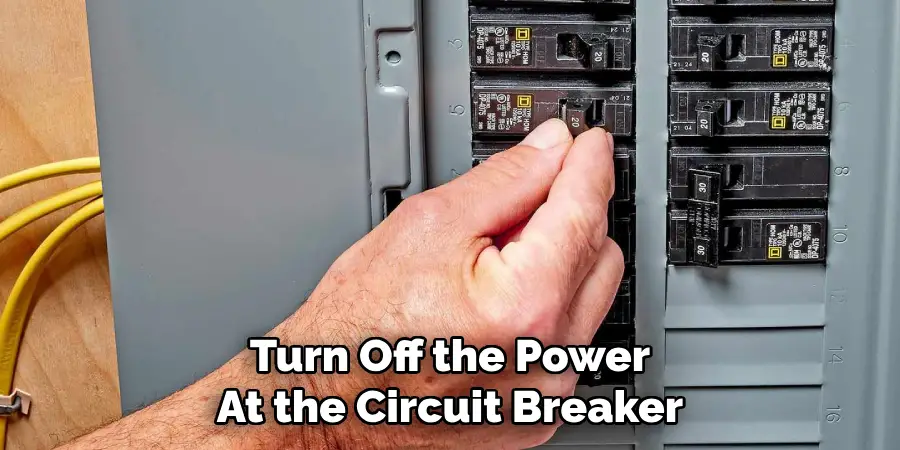

Step 1: Turn Off the Power at the Circuit Breaker

Before beginning any electrical work, it is crucial to turn off the power to the circuit that will be connected to the shop lights. Locate the appropriate circuit breaker in your main panel and switch it to the “off” position. To confirm that no electricity is flowing, use a circuit tester on the fixtures and outlets associated with that circuit. This step ensures that you can work safely without the risk of electric shock.

Step 2: Understanding Electrical Codes

Before starting any wiring project, it is important to familiarize yourself with local building and electrical codes. These regulations exist to ensure public safety, and compliance is mandatory. Adhering to these codes not only enhances personal safety but also helps prevent potential fire hazards and ensures legal compliance, thereby avoiding costly fines or rework.

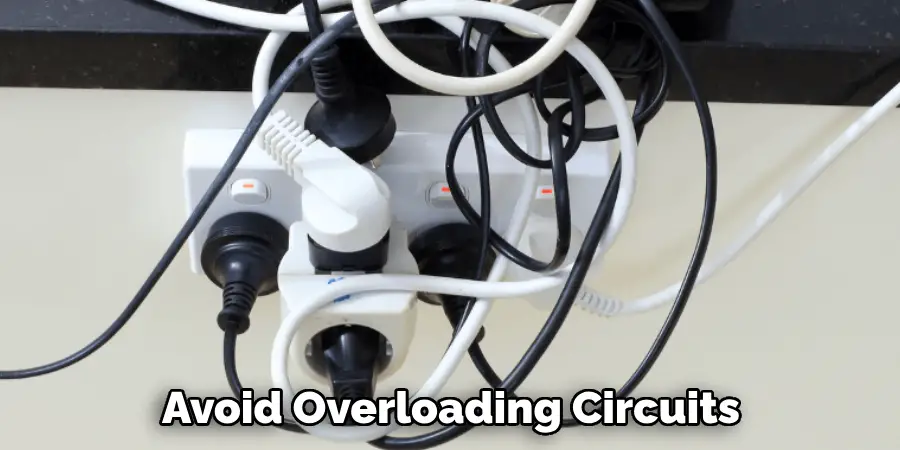

Step 3: Avoiding Overloaded Circuits

To prevent overloading and causing breaker trips or fire risks, you must calculate the total electrical load on a circuit. This involves adding up the wattage of all connected devices and fixtures to ensure it does not exceed the circuit’s capacity. If the load is too high, consider installing additional circuits to distribute the power demand safely.

Planning the Layout for Your Shop Lights

Step 1: Determine Lighting Requirements

To effectively plan your shop lighting, determine the number of fixtures required. This depends on the size of your workspace, the desired light intensity, and the strategic placement of each unit. Assess the area’s dimensions, considering the height and span, to gauge coverage. Light brightness is measured in lumens, while energy consumption is expressed in wattage. Typically, brighter work areas like benches may require higher lumens, while general spaces demand less. Calculate the total lumens necessary, balancing wattage and energy efficiency to select suitable lighting that fulfills the demands of various zones in your shop.

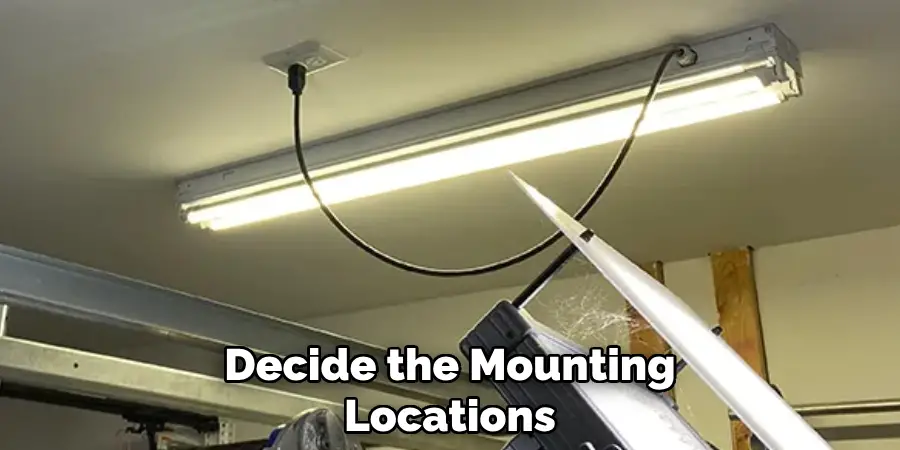

Step 2: Decide the Mounting Locations

Once you’ve determined how many lights are needed, the next step is to decide where to mount them for optimal coverage. Guiding principles involve placing lights to minimize shadows and evenly illuminate the entire space. Evaluate the layout of your workstations and storage areas to avoid dark zones and enhance visibility. Ensure even spacing between fixtures to prevent inconsistencies in lighting intensity. Strategic placement contributes to safety and productivity, prioritizing clear visibility in task-specific areas.

Step 3: Identify Power Sources

Identify a reliable power source to supply your shop lights, such as an existing outlet or install a dedicated switch. This involves checking accessibility, capacity, and compliance of your chosen source. Plan a clear wire route from the power source to each light fixture, taking into account intersections such as walls or ceilings which may require drilling or additional support. Prioritize ease of access for maintenance while ensuring routes adhere to safety standards, especially around damp or high-traffic areas.

Step 4: Measure Wire Lengths

Accurate measurement of wire lengths is crucial, ensuring each link from the power source to the lights is well-prepared. Use a tape measure to determine the path the wire will take, carefully including extra length for slack. Overly taut wires risk organizational disruption and may suffer wear over time. Allowing slight surplus caters to adjustments during installation, preventing strain on connections and accommodating future modifications efficiently.

How to Wire Shop Lights: Step-by-Step Instructions

Step 1: Mount the Shop Lights

Begin by installing the shop lights on your ceiling or wall, following the manufacturer’s instructions closely. Use either a drill or a screwdriver to firmly attach the mounting brackets, ensuring stability. Hold the fixture up to your chosen spot, mark the bracket holes on the surface, and drill pilot holes if necessary to make the screws secure. Double-check that the light fixture is level and aligned with the desired positioning to provide optimal illumination across the workspace.

Step 2: Run the Electrical Wires

Next, run the electrical wires from your power source to the shop lights. Thread the wires through the walls or along the ceiling, using wire staples or conduits to protect them from damage. When routing the wires, consider the shortest and safest path, avoiding sharp angles or places where the wire might be easily disturbed. If your layout requires it, drill holes to pass the wires through structural barriers, avoiding any existing electrical or plumbing infrastructure.

Step 3: Strip the Wire Insulation

Use wire strippers to carefully remove approximately ¾ inch of insulation from the ends of each wire (black, white, and ground). While stripping, handle the wires gently to prevent nicking or damaging the conductive core. Ensuring that you have a clean strip is crucial because it facilitates a strong, reliable connection with the light fixture. Always cut away from yourself, and double-check your work to confirm that the exposed copper extends sufficiently for a secure joint.

Step 4: Connect the Wires to the Lights

Connect the wires from the power source to the corresponding wires on the shop light. Begin with the black (hot) wire, twisting it together with the fixture’s matching wire, then proceed with the white (neutral), and finally the green or bare (ground) wire. Use wire nuts to secure the connections, twisting them tightly to ensure a secure fit. Properly connecting and securing wires according to color codes prevents electrical mishaps and ensures effective operation of the lighting system.

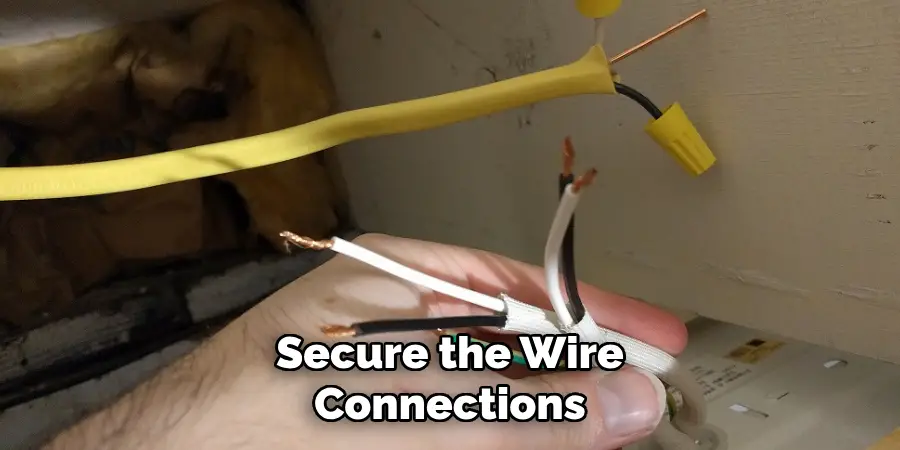

Step 5: Secure the Wire Connections

Wrap electrical tape around the wire nuts to guarantee they remain tightly secured and insulated. Make sure the tape extends slightly below the wire nut for added stability. Tuck the wires neatly into the junction box or fixture housing to prevent any hanging or exposure to external movement, securing them into place without strain. This maintains order and helps avoid potential damage or disconnection over time.

Step 6: Connect the Ground Wire

Attach the ground wire (green or bare copper) from the circuit to the shop light fixture’s grounding screw or wire. This essential step is vital for ensuring safety by preventing electrical shocks. A properly grounded system will redirect any unintended electrical currents, mitigating the risk of shock or fire. Double-check the connection for tightness and correctness.

Step 7: Attach the Light Fixture Cover

Finally, carefully place the cover on the light fixture, ensuring it is positioned correctly and secures any loose wires inside the housing. Double-check that no wires are exposed before closing and securing the fixture completely. Follow the manufacturer’s instructions for aligning and fixating the cover, ensuring it is snug and locked into place to protect the internal wiring and bulb.

Testing the Installation

Step 1: Restore Power to the Circuit

Once all wiring and connections are complete, it’s time to restore power to the circuit. Begin by ensuring that the circuit breaker is in the “off” position to avoid any accidental currents. Double-check all connections, confirming that each wire is securely fastened and in the correct position according to the wiring guidelines. Safely flip the switch back to the “on” position at the circuit breaker, cautiously preparing to test your installation. It’s crucial to ensure everything is in order before energizing the system to prevent any potential short circuits or electrical hazards.

Step 2: Test the Shop Lights

Now that power has been restored, turn on your newly installed shop lights using their designated switch. Observe if all the lights illuminate as expected, offering full brightness throughout the workspace. In case the lights do not turn on, start troubleshooting by inspecting the connections, examining the circuit breaker, and confirming that each wire nut is firmly attached. Consider checking any switches or controls in the circuit to ensure they are functioning properly.

Step 3: Check for Flickering or Dimming

Once the lights are on, watch carefully for any flickering or dimming, which can signal loose connections or insufficient wiring. If flickering is detected, return to the wiring to reassess each connection. Ensure that all wires are securely attached and the wire nuts are tight. Adjust any issues you find, verifying the integrity of both the fixtures and the overall installation. Consistent, effective lighting is vital for safety and productivity, making it important to address any anomalies promptly.

Optional: Wiring a Switch for the Shop Lights

Adding a switch to your shop light installation provides convenience and control over your lighting system. Begin by selecting an appropriate switch location that is easily accessible but safe from accidental bumps. Before proceeding, ensure the power is turned off at the circuit breaker to prevent electrical hazards. Run a new electrical wire from the light fixture to your chosen switch location, carefully threading it through the wall using existing conduits or creating new spaces as needed.

At the switch, connect the incoming wire’s black (hot) wire to one terminal on the switch and the outgoing wire’s black (hot) wire to the other terminal. The white (neutral) wires should remain connected directly, and the ground wires should be bonded together and connected to the switch’s grounding screw if applicable. Once the wiring is complete, secure the switch in its electrical box and attach a cover plate.

Finally, restore power and test the switch’s functionality. Flip the switch to ensure it effectively controls the shop lights, enabling them to turn on and off without issues. This simple addition enhances the usability of your lighting system, making it easier to illuminate your workspace as needed.

Maintenance and Safety Tips for Shop Lights

Tip 1: Inspect the Wiring Regularly

In a workshop environment filled with tools and heavy equipment, it’s crucial to regularly inspect the wiring of your shop lights for signs of wear, tear, or damage. Prompt identification and repair of any issues can prevent electrical failures or accidents, ensuring a safe work environment.

Tip 2: Replace Bulbs as Needed

To maintain optimal lighting conditions, replace bulbs promptly when they burn out or dim. This enhances visibility in your workspace and helps prevent undue strain on the electrical system, which can occur when malfunctioning bulbs remain in use.

Tip 3: Clean the Light Fixtures

Clean your light fixtures regularly to keep them free from dust and debris. A simple wipe-down with a soft, dry cloth can ensure the fixtures remain bright and efficient, thereby maximizing their performance and extending their lifespan.

Tip 4: Avoid Overloading Circuits

Be mindful not to overload electrical circuits by adding excessive lights. Overloading can lead to circuit breaker trips or, in worse cases, fire hazards. Distributing the electrical load evenly maintains your lighting system’s overall safety and efficiency.

Conclusion

Successfully completing a project on how to wire shop lights involves several essential steps: securely connecting wires, installing a switch, and properly testing the installation. Emphasizing safety, always ensure that you follow local electrical codes and standards. Remember the crucial step of turning off the power before any electrical work to prevent hazards. Thoroughly test the lights post-installation to verify their functionality. With these guidelines, DIY enthusiasts can confidently approach this task, creating a well-lit and functional workspace that enhances both productivity and safety.