Are you tired of snapping away at your brake lights every time you want to back up your vehicle? If so, don’t worry – rewiring your brake lights is easier than you may think! In this blog post, we’ll discuss the basics of how to wire brake lights correctly and efficiently. We’ll explain which items are necessary for proper wiring and provide step-by-step directions on how to achieve the best result with minimal effort.

By the end of our guide, you should be well-equipped with a basic understanding of wire brake lights in order for them to properly illuminate when braking. So keep reading if you’re looking for an easy way to let other motorists know when it’s time for them to stop!

What Colors Are Brake Lights Wiring?

The three wires used to wire brake lights are typically color coded as follows: black for the ground, red for running/brake power, and yellow for the turn signal. Some vehicles may also have a green wire that provides power when in reverse gear.

When wiring brake lights correctly, it’s important to make sure each of these colors is matched up correctly with its respective function. Be sure to consult your vehicle’s manual or owner’s guide before attempting any wiring work! Additionally, having an electrical diagram of the system can be extremely helpful in understanding how everything connects.

Before beginning any electrical work on your vehicle, make sure to disconnect the negative cable from the battery. This will ensure that no electricity can flow through the system and cause a potential shock hazard.

Additionally, it’s always recommended to double-check before any wiring, even if you think you know what you’re doing – a simple mistake can end up costing more money down the line! All brake light wiring should be done according to local laws in your area.

Once all safety precautions have been taken, it’s time to begin the installation. Make sure that all wires are properly connected and insulated with wire splicing connectors such as crimp caps or soldered butt connectors.

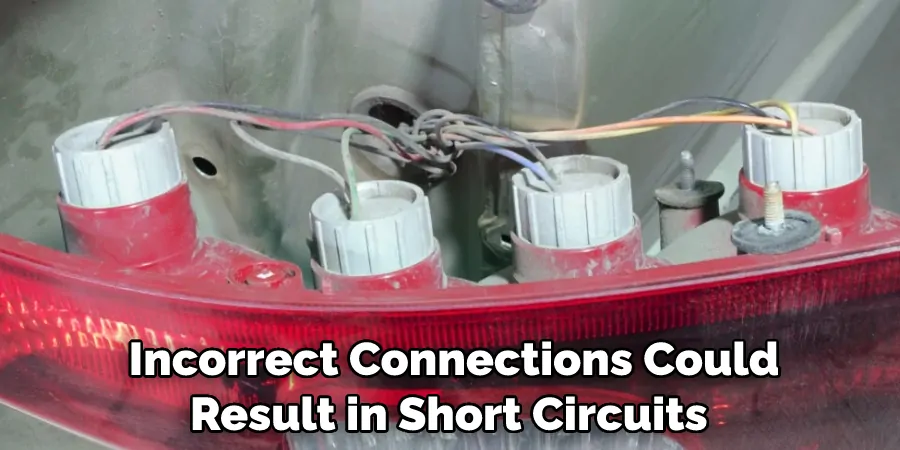

Be very careful not to mix up any of the colors – incorrect connections could result in short circuits or other issues that can damage your vehicle’s electrical systems. When finished, carefully test out your handiwork before taking to the roads – you don’t want any surprises!

We hope our guide on how to wire brake lights has been helpful for you. Remember, safety should always come first when working with vehicle electrical wiring. If you ever feel uncertain about a certain step or are worried about potentially making a mistake, it’s better to seek professional help. With the right guidance and information, you can easily get your brake lights wired correctly in no time!

10 Methods How to Wire Brake Lights

1. Get the Right Tools

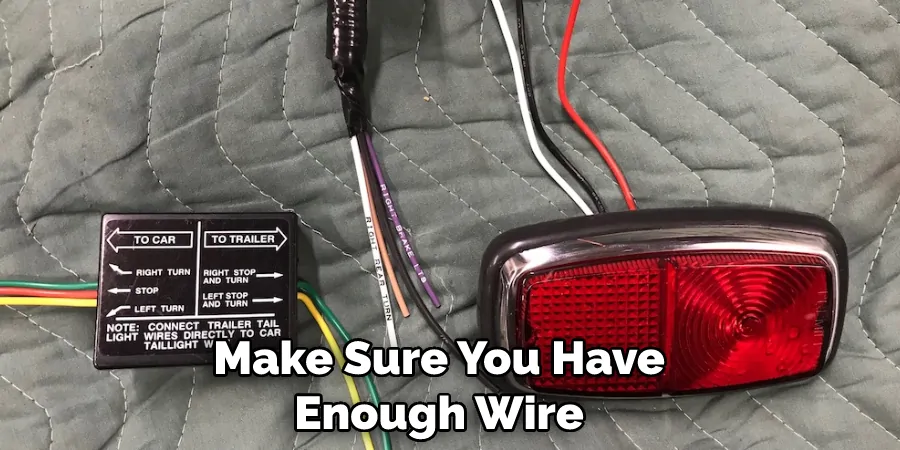

The first step in wiring brake lights is to gather the tools you will need. You will need a screwdriver, wire strippers, electrical tape, and a drill. You will also need to purchase some wire and connectors. If you are installing multiple brake lights, make sure to get enough wire and connectors to complete the job.

However, keep in mind that if the brake lights are wired in series, you will only need one wire and two connectors. To ensure that your brake lights are properly wired, make sure to use good-quality wire and connectors.

2. Remove the Tail Light Housing

Once you have gathered your tools, the next step is to remove the tail light housing. This is typically done by removing a few screws that hold the housing in place. Once the housing is removed, you will have access to the wires that need to be connected.

To ensure the housing is reinstalled correctly, you can use a piece of colored tape or marker to note which screw goes where. While some tail light housings are held with screws, others may be held on with clips or tabs. In this case, they will need to be carefully removed and then reinstalled back onto the vehicle.

3. Strip the Wires

Using your wire strippers, strip about ½ inch of insulation off of each wire that needs to be connected. Be careful not to strip too much insulation off, as this can cause problems later on. When finished, you should have four wires that are ready to be connected.

If your brake light kit includes a bulb holder, attach the wires to this now. Although the wiring procedures may vary, you should have a hot/power wire (usually red), a ground wire (usually green or white with a green stripe), and two brake light wires (usually brown and gray).

4. Connect the Wires

Once the wires are stripped, it’s time to connect them. Twist each wire around its counterpart and then twist a connector onto each pair of wires. Make sure that the connection is tight so that there is no chance of it coming loose. If the wires are too short, you can purchase wire extensions to connect them together.

Once all of your connections are made, it’s time to test them. If the brake lights do not turn on when you press the brake, check that all of your connections are secure and that your bulbs are in good condition. If everything looks in order and your brakes still don’t work, you may need to consult a mechanic.

5. Tape up the Connection

Once the wires are connected, use electrical tape to tape up the connection. This will help to prevent any moisture or dirt from getting into the connection and causing problems later on. Make sure to wrap the electrical tape around each connection multiple times. This can help ensure that the connection will remain secure and will not cause any issues in the future.

However, be careful not to use too much tape as this can make the connection difficult to access later on. While taping up the connections, make sure to keep any excess wire out of the way. This will help to avoid any unnecessary damage and make it easier to access the connection in the future.

6. Drill a Hole for the Wire

The next step is to drill a hole for the wire to pass through. Drill a hole in the tail light housing large enough for the wire to pass through without being too snug. Make sure you have enough wire to reach the brake switch. If not, add a few extra inches of wiring.

To ensure a proper fit, measure the circumference of the wire before drilling. While drilling, keep the drill bit straight and perpendicular to the tail light housing. If at any time the drill bit deviates from your desired path, stop and start again.

7. Feed the Wire Through the Hole

Feed the wire through the hole you just drilled and then secure it in place with a zip tie or other similar device. Make sure that the wire is secure so that it doesn’t come loose while you are driving. Once it is secure, you can connect the wire to the brake light switch.

This will ensure that when you press your brakes, the brake lights will turn on. Once everything is hooked up, you can test the brake lights to make sure they are working properly. If everything looks good, you’re ready to hit the road!

8. Reconnect the Tail Light Housing

Once the wire is in place, reconnect the tail light housing and screw it back into place. Be sure not to overtighten the screws as this can strip them or break them entirely. Double-check the connections to make sure they are secure. Test the brake lights once again to make sure that everything is working properly before taking your vehicle out on the road.

9. Test your Brake Lights

Before you go driving off, it’s important to test your brake lights to make sure they are working properly. Have someone stand behind your car and depress the brake pedal while you observe the brake lights from inside your car. If they are working properly, they should illuminate when you depress the brake pedal.

10. Enjoy the Ride

Once you have verified that your brake lights are working properly, it’s time to take your car for a spin and enjoy the ride. As you drive, make sure to periodically check on your brake lights to ensure that they are still working properly. If at any time you notice that one of your brakes is not illuminated when stepped upon, it may be an indication of a problem with your wiring and should be addressed immediately.

Conclusion

In conclusion, wiring brake lights is not a difficult process once the proper tools and information have been acquired. However, it is important to understand how electricity works and which cables go to what points before beginning. If you are unsure of how to wire brake lights, it is best to leave the job for a professional. Although you may know what needs to be done in theory, safety must always come first, and having a professional’s eye can save you from making an irreversible mistake.