Converting from halogen to LED lighting is a smart and sustainable choice. LEDs are known for their superior energy efficiency, consuming significantly less power than halogen bulbs, which leads to reduced electricity bills and a smaller carbon footprint. Moreover, LEDs have a longer lifespan, lasting up to 25 times longer than traditional halogen bulbs, which means fewer replacements and less waste.

They also emit considerably less heat, making them safer and reducing air conditioning costs in warmer environments. Retrofitting involves replacing your existing halogen bulbs with equivalent LED options, which is often straightforward. Common halogen lamps, such as GU10, MR16, or standard household bulbs, are frequently transitioned to LED due to these advantages. This conversion benefits both indoor and outdoor lighting applications, offering brighter illumination and enhanced durability. Understanding “how to convert a halogen lamp to led” is crucial for achieving efficient, eco-friendly lighting solutions.

Tools and Materials Needed

Gathering the appropriate tools and materials is essential to converting a halogen lamp to LED, ensuring a successful and safe installation.

LED Replacement Bulbs: Begin by selecting the right LED bulbs that are compatible with your existing fixtures. Pay close attention to the base types, such as GU10 or MR16, and make sure they align with your current setup. Understand the concept of wattage equivalence, where a lower wattage LED bulb, like a 5W, can effectively replace a 50W halogen bulb, offering similar light output with less energy consumption.

Transformer (if needed): Some low-voltage halogen systems, particularly MR16, may require an LED driver or transformer for compatibility. This switch is necessary to handle the different electrical demands of LEDs and avoid flickering or inefficiency.

Screwdriver: A handy tool to open the light fixture and gain access to the bulb housing.

Voltage Tester (for safety): Ensures that the power is completely off before you start working on any electrical components, preventing shocks or accidents.

Ladder (if applicable): If the lamps are ceiling-mounted or in a hard-to-reach area, a sturdy ladder will help you reach them safely.

Safety Precautions

Turn Off the Power at the Circuit Breaker:

Ensuring safety during the conversion process is paramount, and one of the primary steps is to turn off the power at the circuit breaker. This action is crucial, especially when dealing with recessed or hard-wired fixtures, as it completely cuts off the electrical current, minimizing the risk of electrical shocks. Even if you are dealing with plug-in lamps, removing the plug from the socket is essential for safety. By guaranteeing no power flowing to the fixture, you can work confidently without accidental electrocution.

Use a Voltage Tester:

Before you start handling any electrical components, confirming that no residual current is running to the fixture is vital. Use a voltage tester for this purpose. To do this, simply follow the instructions on the tester to ensure it is functioning properly, then test the fixture to confirm that it is safe to proceed. This step provides an additional layer of security, ensuring you work in a no-voltage environment.

Wear Protective Gear:

Protective gear is an important safety measure when handling light bulbs and working on fixtures. Use safety goggles to shield your eyes from potential debris or accidental bulb breakage. Additionally, wear gloves to protect your hands from sharp edges and to prevent burns, as halogen bulbs can remain hot even after being turned off. These precautions will help safeguard against injuries and ensure a smooth and safe conversion process.

Identifying the Type of Halogen Lamp

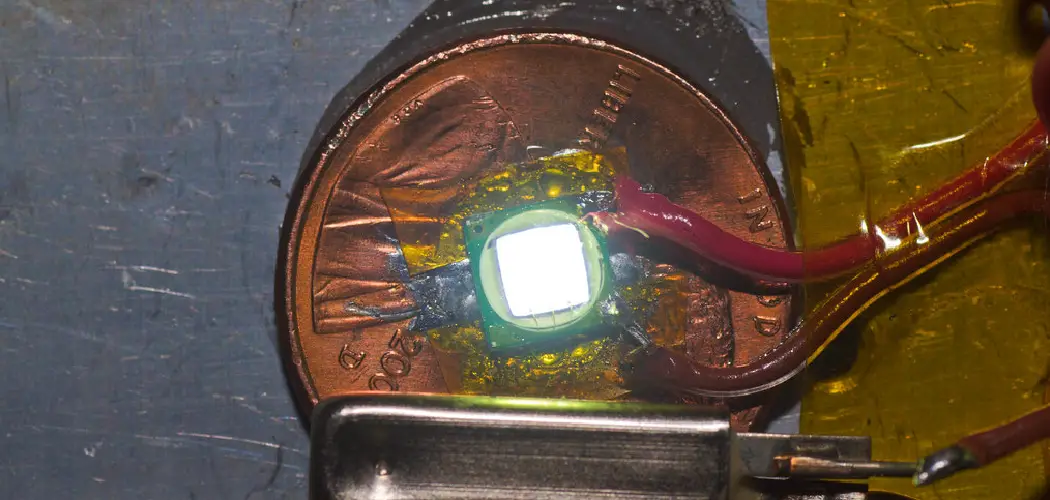

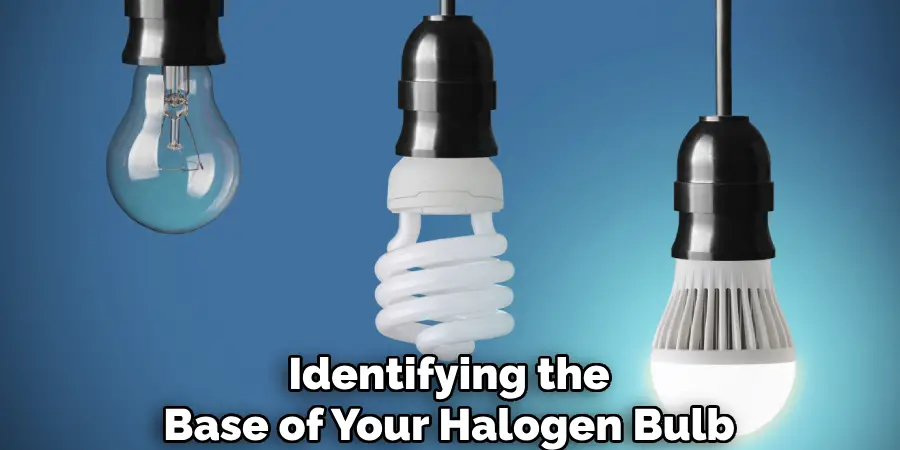

Check the Base of the Bulb:

Identifying the base of your halogen bulb is crucial for ensuring compatibility when purchasing LED replacements. There are several common base types to be aware of: GU10, MR16, E27, and G9. Each base type has a unique design that enables it to fit into specific fixtures. For instance, GU10 bulbs have a bayonet-style base with two pins that twist into place, whereas MR16 bulbs have two straight pins and typically work in low-voltage settings.

E27 bases, known as Edison screws, are larger and common in household lamps, and G9 bulbs have looped pins used in compact fixtures. Understanding these base types is essential, as they must match your fixture to establish a proper electrical connection and fit.

Determine if the Bulb is Low or High Voltage:

Halogen lamps operate at either low or high voltage, significantly impacting how you approach the conversion. Low-voltage bulbs, like the MR16, typically use 12V and require a transformer to reduce the voltage from the standard household supply. When converting to LED, you might need an LED-compatible driver to manage these voltage requirements effectively.

On the other hand, high-voltage bulbs, such as GU10, use 120V or 240V and can typically be replaced with LEDs directly without additional modifications. Ensuring the voltage compatibility of the new LED bulbs with your existing setup is key to avoiding flickering or performance issues.

Wattage Compatibility:

Wattage compatibility is essential to maintain the desired brightness level when converting to LED. Halogen bulbs are often labeled with their wattage, which represents the power they use. For example, a halogen bulb may indicate it’s 35W to 50W. When transitioning to LEDs, look for an equivalent LED wattage, such as a 5W LED, which provides similar light output to a 35W to 50W halogen but with significantly less energy consumption. This wattage equivalence ensures that your lighting remains consistent while taking advantage of LEDs’ energy efficiency.

How to Convert a Halogen Lamp to Led: Removing the Halogen Bulbs

Step 1: Allow the Bulbs to Cool

Before removing your halogen bulbs, allow them to cool down fully. Halogen bulbs operate at high temperatures and can become extremely hot during use. Handling them while hot can cause burns, and the sudden temperature change can also cause the bulbs to shatter. Waiting for them to cool decreases the risk of injury and damage, ensuring a safer removal process.

Step 2: Unscrew or Twist the Bulbs to Remove

The method for removing halogen bulbs depends on the type of base they use:

- Screw-in Base (e.g., E27): For bulbs with an E27 or similar screw-in base, simply grasp the bulb firmly and unscrew it by turning counterclockwise. Doing so will safely detach the bulb from the socket without additional tools.

- Twist-Lock Base (e.g., GU10): These bulbs typically use a bayonet-style twist-lock mechanism. To remove a GU10 bulb, gently press down and twist the bulb counterclockwise until it unlocks from the socket and can be pulled away.

- Push-Fit Base (e.g., MR16): For MR16 bulbs, carefully pull the bulb out of the socket. Avoid pulling too vigorously, as this could damage the pins or socket.

While handling the bulbs, use gloves or a cloth to minimize direct contact and prevent breakage. Take extra care with older bulbs that may be more fragile, as well as those containing materials like mercury that require careful disposal.

Step 3: Inspect the Socket

Once the bulbs are removed, inspect the sockets carefully. Look for any signs of damage, such as burn marks, corrosion, or loose components, which might indicate the socket needs replacement or maintenance. Ensuring the socket’s integrity is critical for the successful installation and functioning of LED bulbs, as it guarantees proper connection and electrical safety.

How to Convert a Halogen Lamp to Led: Installing the LED Bulbs

Step 1: Choose the Correct LED Bulb

Selecting the right LED bulb is essential for a successful conversion from halogen to LED lighting. Begin by ensuring that the LED bulb matches the base type of your previous halogen bulb, whether it be GU10, MR16, E27, or G9. It is also crucial to match the voltage requirements—high-voltage or low-voltage—to avoid electrical issues. Additionally, consider the color temperature of the LED bulbs.

A “warm white” LED (around 2700K-3000K) will mimic the soft glow of traditional incandescent bulbs, ideal for living spaces, while a “daylight” LED (around 5000K-6500K) is brighter and suitable for task-oriented areas like kitchens or offices. Finally, ensure the LED’s brightness, measured in lumens, aligns with your lighting needs to maintain the desired ambiance and function in your space.

Step 2: Direct Replacement for High-Voltage Fixtures (e.g., GU10 or E27)

For fixtures with high-voltage halogen bulbs, such as GU10 or E27, replacing them with LEDs is straightforward. To install a screw-in LED bulb, simply insert the bulb into the socket and twist clockwise until it is firmly in place. For twist-lock bulbs, gently insert the LED into the fixture and rotate it to secure it. With push-fit bulbs, insert the LED bulb straight into the socket until it is seated securely. Ensure that the LED bulb makes full contact with the socket to prevent flickering or a loose connection.

Step 3: Transformer Replacement for Low-Voltage Fixtures (e.g., MR16)

Converting low-voltage halogen systems, like those using MR16 bulbs, to LED may require a transformer compatible with LED technology. Begin by assessing whether your existing transformer supports LED bulbs or if a replacement is necessary. If so, disconnect the old transformer by carefully following manufacturer instructions, and wire in a new LED-compatible driver.

Ensure that both the transformer and the LED bulbs are voltage-compatible before re-powering the fixture to prevent issues. Verify all connections are secure, and test the lighting to confirm that the new setup is functioning correctly. This attention to detail ensures a seamless transition to energy-efficient LED lighting.

Testing the New LED Installation

Step 1: Turn Power Back On

Before testing the newly installed LED bulbs, it’s vital to safely restore power to your lighting fixtures. Return to your circuit breaker panel and locate the breaker that corresponds to the fixture you’ve been working on. Flip the breaker switch back to the “on” position. If you’ve unplugged the fixture for installation, simply plug it back into the outlet. Ensure all connections are secure and that there are no signs of damage or loose wiring in the process.

Step 2: Test the LED Lights

With power restored, it’s time to switch on the LED lights and assess their performance. Flick the light switch to the “on” position and observe the bulbs. Properly functioning LEDs should illuminate instantly without flickering. If you notice flickering, dimming, or uneven lighting, it may indicate compatibility issues with the existing transformer or dimmer switch, especially if these components are not designed for LED technology. In such cases, recheck connections and consider consulting with an electrician if challenges persist.

Step 3: Adjusting a Dimmer Switch (if applicable)

For installations with dimmer switches, some adjustments may be necessary as older models designed for halogen bulbs might not function well with LEDs. If flickering or other issues occur when dimming, consider replacing the dimmer switch with a version specifically labeled for LED use. When installing a new dimmer, follow the manufacturer’s instructions and ensure it is properly rated for the total wattage of your LED setup. This adjustment will provide smoother dimming action and prevent potential disruptions in your lighting ambiance.

Conclusion

Converting halogen lamps to LED lighting involves a thoughtful process that ensures efficiency and safety. The journey begins with understanding how to convert a halogen lamp to LED by selecting the right LED bulb matching both the base type and voltage. Assess compatibility with existing transformers, especially in low-voltage setups, and consider replacing them if necessary to support LED technology. Practice caution by following safe installation procedures to safeguard electrical components and personal safety.

The long-term benefits of switching to LEDs are substantial, offering significant energy savings, reduced maintenance costs due to their extended lifespan, and improved safety with lower heat emissions. This transition not only enhances lighting quality but also contributes to a more eco-friendly environment. If uncertainties arise—particularly with transformers, wiring, or dimmer switches—seeking professional assistance is advised to ensure a seamless and successful conversion process.