Neon lights are a fascinating example of science and art blending harmoniously. Often associated with vibrant urban landscapes and creative signage, they captivate viewers with their vivid glow and striking colors.

At their core, neon lights work through the principles of gas discharge and electric luminescence.

By applying an electrical current to a sealed tube filled with neon or other gases, these lights produce a brilliant illumination that can vary in hue depending on the gas used.

This introduction aims to unravel the science behind neon lights, exploring the elements that contribute to their mesmerizing appeal and widespread use. In this blogpost on how do neon lights work, we will delve into their history, construction, and functioning.

Why Do People Still Use Neon Lights?

The history of neon lights dates back to the late 19th century when French chemist Georges Claude first developed a method for synthesizing neon gas. However, it wasn’t until the early 20th century that neon lights began to emerge as a popular lighting source.

With their distinctive glow and vibrant hues, neon lights quickly caught on in advertising and signage, becoming a symbol of modernity and progress. Today, despite advances in LED technology, neon lights continue to hold a special place in our hearts and urban landscapes.

They evoke nostalgia, add character to city streets, and create an ambiance unlike any other lighting source.

Needed Materials

Gas, Glass Tubes, and Electricity: The Three Elements of Neon Lights

There are three essential components required for neon lights to function: gas, glass tubes, and electricity. These elements work together in a delicate balance to produce the iconic glow associated with neon lights.

Gas:

As mentioned earlier, neon gas is the key ingredient that gives these lights their name. Neon gas emits a reddish-orange color when activated by electricity, but other gases can also be used to produce varying colors such as argon (blue), helium (pink), and carbon dioxide (white).

Glass Tubes:

The second component of neon lights is the glass tube or bulb, which contains the gas. These tubes are typically made from thin glass that can withstand high temperatures and contain two metal electrodes at each end. The inside of the tube is coated with a phosphor powder that glows when struck by electricity.

Electricity:

The final element needed for neon lights to work is electricity. When an electrical current is passed through the gas-filled glass tube, it ionizes the gas particles, causing them to emit light.

The unique combination of gases used in neon lights produces a wide spectrum of colors, making them ideal for creating vibrant and eye-catching displays.

8 Simple Step-by-step Guidelines on How Do Neon Lights Work

Step 1: Production of Neon Gas

The production of neon gas is the foundation for creating neon lights. Neon is a noble gas found naturally in the Earth’s atmosphere in trace amounts, making up less than 0.0018% of the air we breathe.

To produce neon gas for commercial use, it must first be extracted from the atmosphere. This process involves air separation techniques, such as fractional distillation, which cools the air until it liquefies. This allows for the separation of gases based on their boiling points.

As the air is warmed, different gases evaporate at different temperatures, and neon is collected along with other noble gases. Once separated, the neon gas is purified and stored under pressure in cylinders, ready for use in neon lighting.

Step 2: Glass Tube Preparation

The glass tubes used in neon lights are typically made from lead glass, which is resistant to heat and can withstand high temperatures. The first step in preparing the tubes is to draw them out into long, thin shapes using a hollow tube and a flame.

Next, the ends of the tube are sealed off with hot flames, leaving a small opening for gas filling. The inside of the tube is then coated with phosphor powder that will later emit light when activated by electricity.

The colors of neon lights can be altered by adding different types and ratios of phosphors.

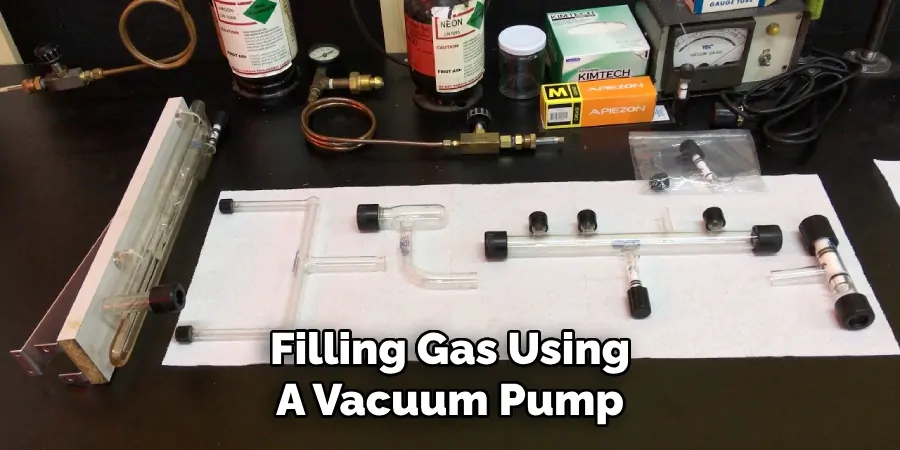

Step 3: Gas Filling

Once the glass tubes are prepared, they are filled with the desired gas using a vacuum pump and specialized equipment. The tube is first evacuated to remove any air or impurities before being filled with the chosen gas at low pressure.

It’s crucial to maintain a controlled environment during this process as any impurities or fluctuations in pressure can affect the quality of light produced.

Step 4: Sealing the Tube

After the gas is filled, the remaining opening of the glass tube is sealed off using high-temperature flames, ensuring that no air can enter. This process also helps to create an electrical seal between the electrodes and the gas inside the tube, allowing for conductivity.

The tube is then cooled, and the electrodes are attached to each end using specialized glass-to-metal seals. These seals also help to maintain the vacuum inside the tube.

Step 5: Wiring and Mounting

With the tube sealed and filled with gas, it’s now time to wire and mount it into a display or sign. The electrodes at each end of the tube are connected to high voltage transformers that produce an electrical discharge, causing the gas particles to emit light.

The wires used for this process are typically made from copper because it has excellent conductivity properties. Once wired, the finished neon lights can be mounted onto structures or displays using brackets or supports.

Step 6: Activation

Now that the neon light is fully assembled, it’s time to activate it by supplying electricity. When a high voltage current is passed through the neon gas, it ionizes the particles, causing them to emit photons of light.

The color emitted depends on the type of gas used in the tube. You may notice that some neon lights take a few minutes to reach their full brightness.

This is because the phosphor coating on the inside of the tube takes time to heat up, and once it does, it emits light more efficiently.

Step 7: Maintenance

Neon lights require regular maintenance and care to ensure they continue to function correctly. This includes checking for any cracks or damage in the glass tubes, replacing faulty electrodes or transformers, and cleaning the tubes regularly to remove any built-up dust or dirt.

Following these maintenance guidelines will help extend the lifespan of neon lights and keep them looking vibrant.

Step 8: Replacement

Eventually, all things must come to an end, and this is true for neon lights as well. Over time, the gas inside the tubes will lose its glow, and the phosphor coating may wear off, resulting in a dim or flickering light.

When this happens, it’s time to replace the entire tube or bulb, as there is no way to refill or repair them once sealed.

Following these simple steps on how do neon lights work, you can now understand the inner workings of neon lights and how they create such eye-catching displays. From production to activation, every step is crucial in creating these iconic and timeless pieces of lighting technology.

So next time you see a bright and colorful neon sign, remember the complex process behind its creation. So go ahead and enjoy the mesmerizing glow of neon lights, knowing that you now have a better understanding of how they work!

Frequently Asked Questions

Q1: Can Any Gas Be Used in Neon Lights, or Does It Have to Be Neon Gas?

A1: While neon is the most commonly used gas in neon lights, other gases such as argon, helium, and krypton can also be used. The different types of gases produce varying color hues, allowing for a wider range of colors in neon lights.

However, neon gas produces the classic and iconic orange-red glow that we typically associate with neon lights.

Q2: How Long Do Neon Lights Last?

A2: The lifespan of neon lights can vary depending on factors such as usage, maintenance, and quality of production.

On average, a well-maintained neon light can last anywhere from 8 to 15 years before needing to be replaced. However, some may last even longer if they are not used frequently or exposed to harsh weather conditions.

Q3: Are Neon Lights Energy-Efficient?

A3: Neon lights are not known for their energy efficiency. They require a high-voltage current to operate, which can be costly in terms of electricity usage. However, advancements in technology have resulted in the production of more energy-efficient neon lights that use less power and last longer.

So, while they may not be the most energy-efficient lighting option, they still offer a unique and captivating visual appeal that cannot be replicated with other types of lighting.

Conclusion

The creation and functioning of neon lights involve a delicate balance between gas, glass tubes, and electricity. With advancements in technology, modern neon lights now come in a variety of shapes, sizes, and colors.

They continue to be used for signage, decorative displays, and even art installations. So, the next time you see a neon light display, take a moment to appreciate the intricate process that goes into creating these beautiful works of art. Thanks for reading this article on how do neon lights work.